Drum Type Fertilizer Granules Screening Machine

- Information

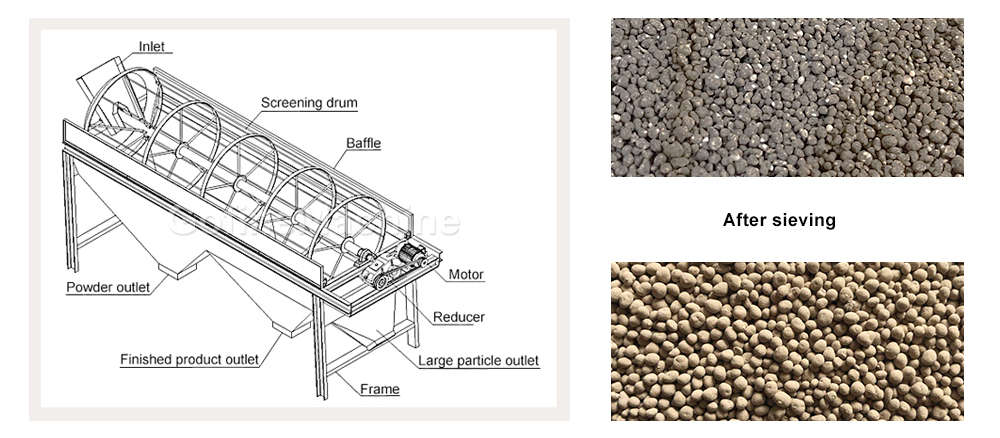

Introduction of Drum Type Fertilizer Granules Screening Machine

The fertilizer screening machine is a piece of equipment used to screen and classify finished fertilizer granules. It can divide the fertilizer into different grades of particles according to its particle size to meet different application needs. The drum type fertilizer screening machine has the characteristics of high efficiency and stability, ensuring the quality and uniformity of fertilizer. At the same time, the screening machine is simple to operate and easy to maintain, which can greatly improve work efficiency. The screening machine is widely used, granular fertilizer, powdery fertilizer, columnar granule, compound fertilizer, etc. can be screened to remove impurities. Improve the utilization rate of fertilizer and achieve better fertilization effect.

Feature of NPK BB Fertilizer Mix Fertilizer Making Machine

1. High efficiency: The material is tumbling through the rotational movement inside the drum, forming a multi-level screening effect and improving work efficiency.

2. High precision: Screens of different specifications can be selected to meet the screening of materials with different particle sizes, and the screening accuracy is as high as 90%.

3. Large output: the circular screen is adopted, the contact area of the material is large, and the output is high. Size specifications support customization

4. Stable and reliable: The equipment has a solid structure, smooth operation and long service life.

5. Strong adjustability: the combined screen is used for easy maintenance and cleaning.

6. Dustproof: Equipped with a sealed isolation cover to avoid dust pollution to the environment during work.

7. Flexibility: It can be combined with supporting production lines, has a high degree of automation and can work continuously.

Working Process of NPK BB Fertilizer Mix Fertilizer Making Machine

The drum screening machine drives the movement of materials through the rotation of the cylinder to achieve the purpose of screening. The material enters the cylinder through the feeding device, and the material continuously rolls and slides inside the drum. Larger materials will automatically roll to the screening outlet along the direction of drum movement, while smaller materials will be discharged through the sieve plate or screen holes. According to the requirements of different materials, the drum speed, angle and screen mesh can be changed to adapt to the screening needs of different materials.

Technical Parameter of NPK BB Fertilizer Mix Fertilizer Making Machine

| Model (m) | Cylinder | Speed (r/min) | Inclination (°) | Power (kw) | Production capacity (t/h) | Dimensions (mm) | |

| Diameter (mm) | Length (mm) | ||||||

| GS1.0x3.0 | 1000 | 3000 | 22 | 2-2.5 | 2.2 | 1-3 | 3500x1400x2200 |

| GS1.2x4.0 | 1200 | 4500 | 17 | 2-2.5 | 3.0 | 3-5 | 4800x1500x2400 |

| GS1.5x5.0 | 1500 | 5000 | 14 | 2-2.5 | 5.5 | 5-10 | 6860x1900x2810 |

| GS1.6x6.0 | 1600 | 6000 | 12 | 2-2.5 | 7.5 | 10-20 | 7300x2000x3000 |

| GS1.8x7.0 | 1800 | 7000 | 11.5 | 2-2.5 | 11 | 20-25 | 9000x2200x3200 |

| GS1.8x9.0 | 1800 | 9000 | 11.5 | 2-2.5 | 18.5 | 20-30 | 11000x2200x3300 |

| GS2.0x10 | 2000 | 10000 | 10.0 | 2-2.5 | 22.0 | 25-40 | 12400x2450x3500 |

Product Details of NPK BB Fertilizer Mix Fertilizer Making Machine