Industrial Plate and Frame Filter Press for Sludge Treatment

- Information

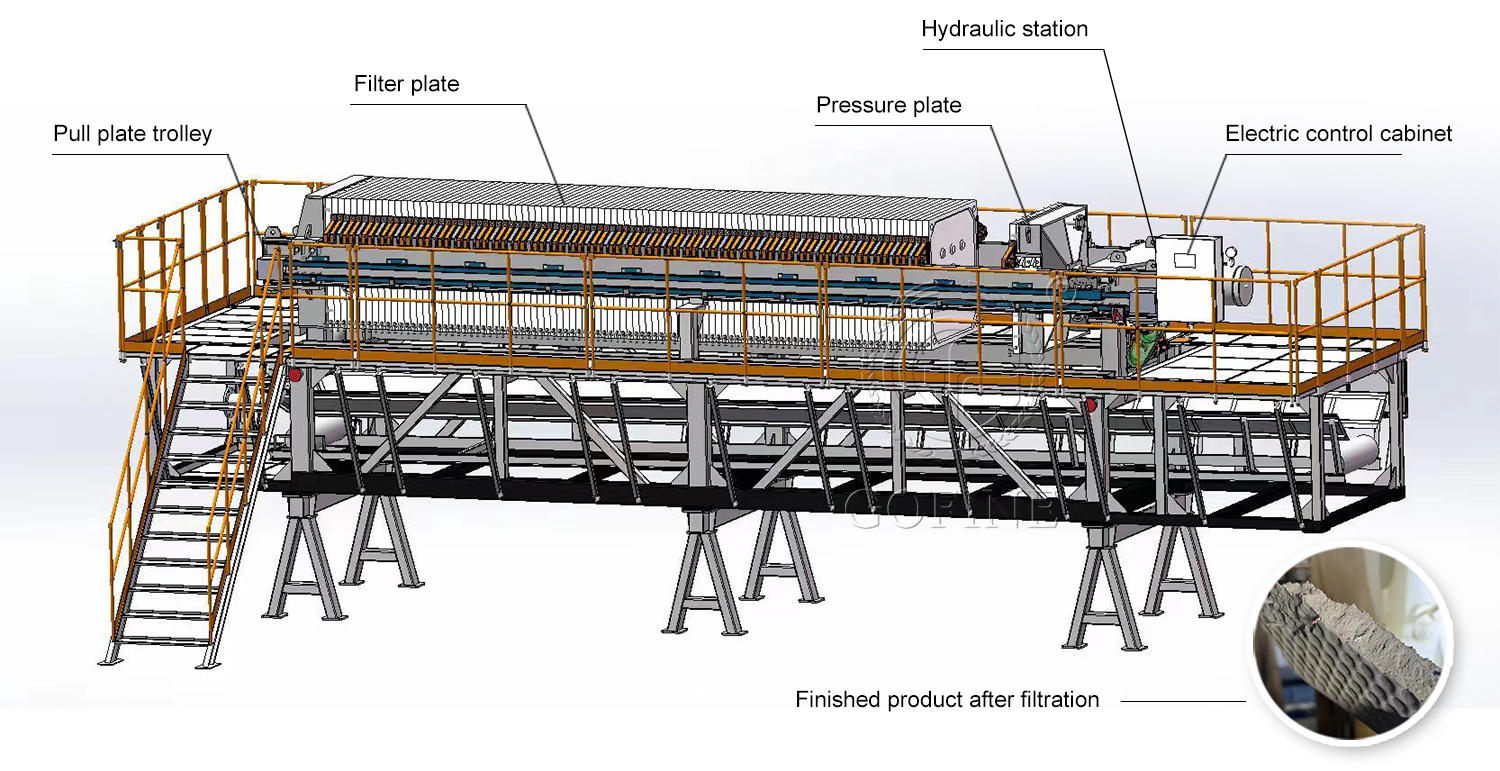

Introduction of Plate and frame filter press

Plate and frame filter press is an industrial equipment used for solid-liquid separation, filtration and extraction. Plate and frame filter press is a filter chamber composed of filter frames. Under pressure, the filter medium is used to separate solids and liquids.

It has the characteristics of high automation, high efficiency, energy saving and environmental protection. It is widely used to deal with solid-liquid separation problems in chemical, pharmaceutical, food, beverage, environmental protection and other industries.

Feature of Plate and frame filter press

1. High efficiency

The plate and frame filter press can effectively separate solid particles and liquid media, and the filtering effect is more thorough.

2. Automation:

The plate and frame filter press can complete automatic feeding, automatic plate turning, automatic plate pulling and unloading.

3. Energy saving and environmental protection

The plate and frame filter press can effectively reduce the water content of solids, save energy, reduce waste emissions, and meet environmental protection requirements during the solid-liquid treatment process.

4. Stable performance

When the plate and frame filter press completes a set of filtering work, it can restart feeding and filtering, which is suitable for long-term industrial production needs.

Application of Plate and frame filter press

| • Kaolin | • Mines | • Coal washing |

| • Mud | • Sewage sludge | • Poultry manure |

| • Juice Filtration | • Olive oil | • Wine sediments |

| • Wastewater treatment | • Dyes | • Potassium chlorate |

| • Graphite | • Ceramic clay | • Bentonite |

| • Rice vinegar mash | • Beer yeast | • Sweet bean paste |

| • Activated carbon | • Bleach | • Starch |

Working Process of Plate and frame filter press

The plate and frame filter press consists of a frame, filter plates, and filter cloth. The frame supports the filter plates, and the gaps between the filter plates form a filter chamber. The hydraulic part of the frame applies pressure to the filter plates to seal them so that they do not leak liquid. The solid and liquid remain in the filter chamber under the filtration of the filter cloth, and the filtrate flows out of the filter chamber through the filter plate guide groove. After the filtration is completed, the automatic plate pulling device will help remove the filter cake, completing the entire set of filtration work.

Technical Parameter of Plate and frame filter press

Industrial and mining categories | Material source and name | Feed moisture % | Filter cake moisture content % | Processing capacity kgds/h.m | |

Municipal wastewater treatment | Mixed sludge (primary sediment and biochemical sludge) | 95-98 | 68-80 | 150-300 | |

| Metallurgical mines | Ore dressing pulp | 40-60 | 14-18 | 1500-3000 | |

| Steel plant | Converter dust removal slag | 55-65 | 20-24 | 1000-2000 | |

| Coal mine | Coal slime washing | 60-70 | 22-28 | 1500-3000 | |

Chemical plant (petrochemical) | Mixed sludge (primary sediment and biochemical sludge) | 95-97 | 75-78 | 150-250 | |

| Brewery | Biochemical sludge | 96-98 | 75-78 | 80-150 | |

Printing and dyeing factory | Biochemical sludge | 96-98 | 70-78 | 80-120 | |

| Tannery | Primary sludge and flotation sludge | 96-98 | 78-80 | 100-150 | |

| Paper mill | Straw pulp | Primary sedimentation sludge | 95-97 | 75-78 | 100-130 |

| Mixed sludge | 96-98 | 76-78 | 80-120 | ||

| Wood pulp | Primary sedimentation sludge | 94-97 | 65-75 | 200-500 | |

| Mixed sludge | 95-98 | 75-78 | 150-300 | ||

| Waste paper pulp | Primary sedimentation sludge | 95-98 | 70-75 | 300-400 | |

| Mixed sludge | 95-98 | 72-75 | 250-380 | ||

Product Details of Plate and frame filter press

1. Plate and frame filter block: The filter block is made of reinforced polypropylene and is formed by one-time pressing. It has high strength, light weight and stable performance.

2. Strong and stable: The frame is made of high-strength steel plate, and the product is strong and stable, durable and wear-resistant.

3. Automation: The plate frame can be automatically flipped to complete the work of pulling the plate and unloading.

Working site of Plate and frame filter press