A complete set of automatic packaging production line solutions

- Information

Introduction

The automatic packaging production line is an efficient and intelligent equipment system designed to meet the needs of modern production. It is widely used in chemical raw materials, organic compound fertilizer production, food processing, animal feed, pet snacks and other fields to achieve fully automated packaging of bagged products of different specifications. Significantly improve production efficiency and packaging quality.

Features of fully automatic packaging machine

High efficiency

Our automatic packaging production line integrates multiple processes, such as bag feeding, weighing, sealing, palletizing, etc., to achieve full automation and improve production efficiency and quality.

Intelligent control

Equipped with an advanced PLC control system, intelligent weighing correction system, and convenient human-machine interface, it is easy to operate and can monitor and adjust production parameters in real time.

Versatility

The production line can handle a variety of packaging specifications and packaging of powdered or granular products to meet different production needs.

Energy saving and environmental protection

The packaging equipment focuses on energy saving and reducing energy consumption. At the same time, the exhaust gas and noise generated during the production process are extremely low, which meets environmental protection standards.

Safety

Multiple safety designs are adopted to ensure the safety of operators and reduce errors and accidents caused by human operation.

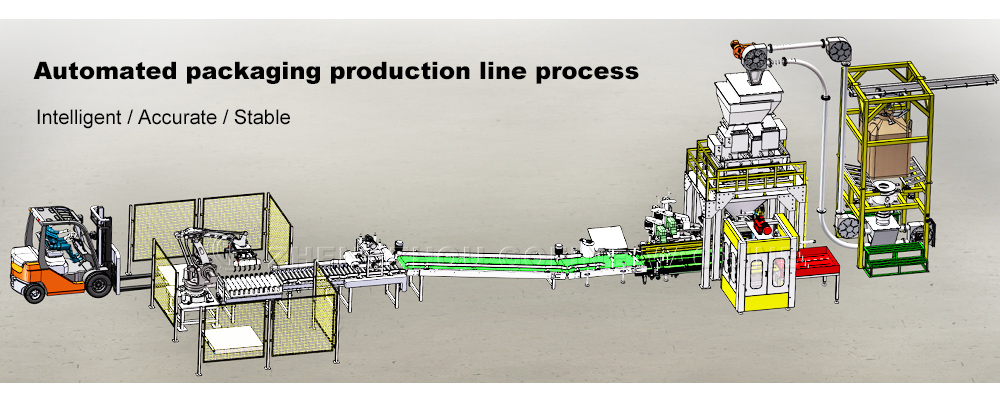

Workflow of a complete set of automatic packaging machines

Fully automatic packaging production lines are usually equipped with different equipment according to the characteristics of the product, packaging requirements, and production scale. Usually, a complete fully automatic packaging production line includes the following main equipment:

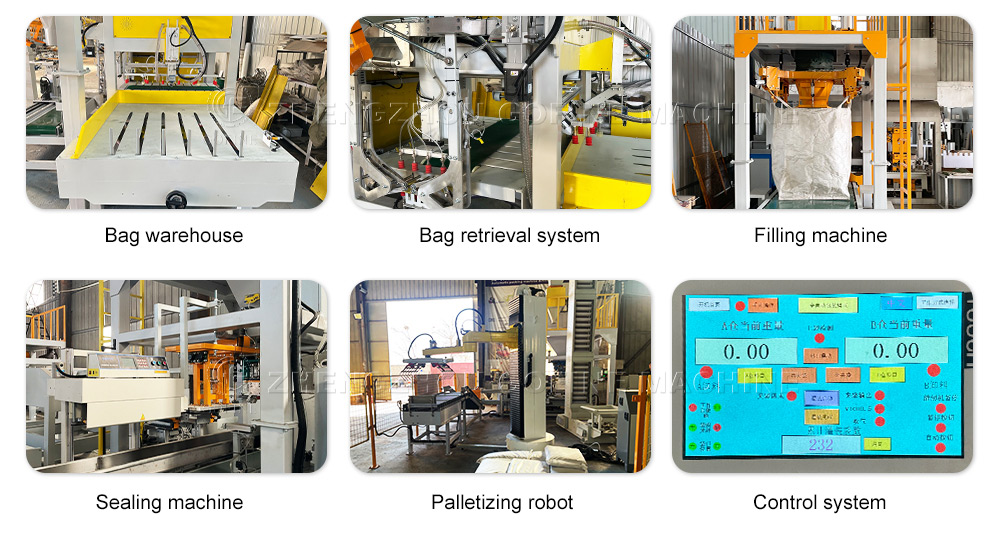

1. Bag warehouse

Also known as an automatic bag supply machine, it is used to store and manage empty bags. It can monitor the inventory status of bags in real time, automatically replenish and manage them, and reduce manual intervention.

2. Bag picking mechanism and bag adjustment mechanism

Automatically put the bags sent from the bag warehouse flatly on the bag clamping port, and adjust them to send them into the bagging mechanism.

3. Bagging mechanism

Automatically put the packaging bags on the unloading port of the packaging machine to facilitate the subsequent production process.

4. Filling mechanism

Automatically fill the materials into the bag according to the weight set by the user, and divide them into three structures: single bin, double bin, and bucketless scale according to the output.

Common packaging machines include:

Powder packaging machine: designed for quantitative packaging of powdered materials, equipped with a dust explosion-proof system.

Particle packaging machine: suitable for products such as fertilizers, feed, and plastic particles, supporting multi-bin weighing.

Ton bag packaging machine: capable of handling more than 500 kg of powder or granular materials, with efficient weighing and packaging functions.

5. Sealing mechanism

Automatically seals the packaging bags after filling, and is divided into sewing machines and heat sealing machines according to the bag material.

6. Palletizing and conveying system

The conveyor and palletizing robot work together to complete the automatic handling and stacking work.

7. Control system

Automatically control the operation of each device of the automatic packaging machine, and connect to the external network monitoring system through the port.

A complete fully automatic packaging production line usually consists of a bag warehouse, bag-taking mechanism, bag adjustment mechanism, bagging mechanism, filling mechanism, sealing mechanism, palletizing robot, conveying system, control system, and other equipment to achieve efficient and automated production. The selection of specific equipment needs to be customized according to product characteristics, packaging requirements, and production scale. Gufeng will provide you with the best solution design and one-stop procurement service.

Application of automated packaging production line

The fully automatic packaging production line can be used for packaging various types of materials, including the following categories:

Granular materials: such as compound fertilizer, slow-release fertilizer, bulk blended fertilizer, feed, grain, pet food, potassium chloride, inorganic fertilizer, plastic, cat litter, etc.

Powdered materials: compost, organic fertilizer, milk powder, coffee powder, seasoning, chemical raw materials, flour, etc.

Liquid materials: water-soluble fertilizer, humic acid, amino acid, foliar fertilizer, etc.

Detail pictures of automated packaging production line

If you want to know more about the equipment, please contact me!