Planting influence and production process of organic fertilizer granules

2024-10-26Organic fertilizer is not only environmentally friendly, but also provides natural nutrients to crops, playing an important role in the field of planting. Organic fertilizer has a positive effect on the growth of many crops, but it is not necessarily suitable for all crops. So, how to produce organic fertilizer suitable for crop growth is a question that many gardeners consider.

Factors affecting organic fertilizers on crops

1. Crop type: Most crops suitable for organic fertilizers are fruits, vegetables, grains and cash crops (such as cotton, coffee, etc.). Some plants with high nitrogen requirements (such as some rice varieties) may not be able to meet their needs with organic fertilizers alone.

2. Soil type: In poor or acidic soils, organic fertilizers can significantly improve soil fertility; in fertile soils, over-the-counter application may lead to nutrient imbalance.

3. Climate conditions: In humid climates, organic fertilizers decompose faster and can release nutrients quickly; in arid areas, fertility is released slowly.

4. Application technology: Excessive or uneven application of organic fertilizers will cause root burns or nutrient deficiencies.

5. Crop growth stage: Different growth stages have different nutrient requirements.

Poor organic fertilizers can cause a series of harms to soil, plants and the environment, such as the spread of pests and diseases, nutrient imbalance, odor pollution, and soil acidification.

How to produce high-quality organic fertilizer

Organic fertilizer is usually made from composted plant residues (such as straw, fallen leaves), animal manure (such as cow dung, chicken manure, sheep dung), kitchen waste (such as food waste, fruits and vegetables), etc.

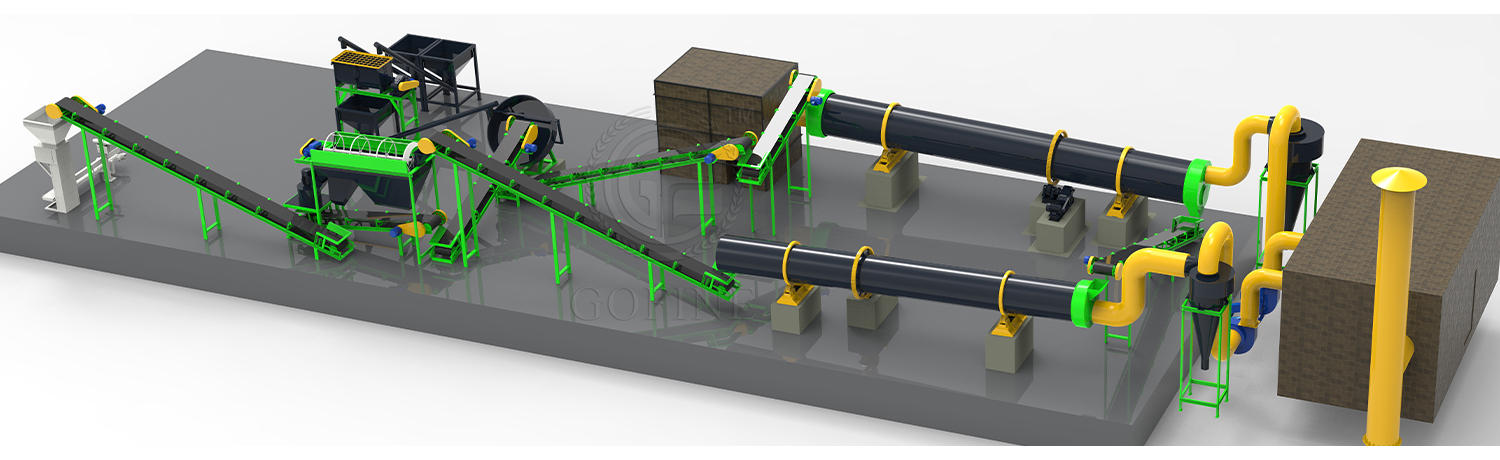

To produce high-quality organic fertilizer granules, you need not only suitable raw materials and scientific process flow, but also professional fertilizer equipment. Next, I will give you a detailed introduction to the process flow of organic fertilizer granule production.

1. Collection of raw materials: Usually organic fertilizer plants are built in areas where raw materials are easy to transport, and the raw materials are transported to the processing site by forklifts or belt conveyors.

2. Composting: With automated and efficient composting equipment, the mixed raw materials are processed into powdered organic fertilizer, which is a crucial step in the production of organic fertilizer.

We have a variety of composting equipment for you to choose from, such as high-temperature fermentation tanks with a small footprint, which can complete harmless treatment in 10 hours; there are also drivable diesel-type composting machines with flexible composting sites; and large-span wheel composting machines, which can achieve multi-track composting and greatly improve production efficiency.

3. Crushing and mixing: Next, you can flexibly match your organic fertilizer formula according to the nutrient ratio.

The vertical chain crusher will be a good choice for you. It can crush the compost material quickly and evenly. Then, add other raw materials you need through the belt conveyor, such as limestone, humic acid, biological bacteria, etc., to effectively improve the nutritional value and applicability of organic fertilizer particles. With a horizontal twin-shaft mixer, this will make your raw materials more evenly mixed.

4. Granulation: This is an important production process! Organic fertilizer granules are usually produced using a disc granulator. Its unique disc structure enables the granulation rate to reach more than 95%. It is an efficient organic fertilizer granulation equipment.

5. Drying and cooling: The granulated organic fertilizer particles are conveyed to the dryer to remove excess water, ensure that the organic fertilizer particles are harder, and improve the stability and storage of the fertilizer particles.

6. Packaging and storage: The production line is usually equipped with an automatic bagging weighing packaging machine, which greatly saves labor costs. After being equipped with a palletizer, the big bags are neatly placed on wooden racks and stored in a dry, ventilated and cool warehouse before being sold to various countries.

The following is our customer case sharing:

Our company is pleased to announce that YES Fertilizer Company has recently successfully purchased a disc granulation line, which is specially designed for the production of high-quality organic fertilizer granules. The introduction of this fertilizer production line not only provides strong support for customers' durian planting projects, but also marks the further advancement of sustainable agricultural practices.

As a crop with high requirements on soil and nutrients, the use of high-quality organic fertilizer is the key to improving yield and quality. Through this disc granulation production line, customers will be able to efficiently convert various organic raw materials into nutrient-rich granular fertilizers. These fertilizers can not only improve soil structure and enhance water retention capacity, but also provide a variety of nutrients required for durian growth, promote root development and fruit ripening.

Our disc granulation production line adopts advanced technology and equipment, which can achieve efficient mixing, granulation and drying of raw materials, ensuring the uniformity and stability of the final product.

Thank YES Fertilizer Company for your trust in us! We will continue to uphold high standards of product quality and excellent customer service to provide customers with the most advanced agricultural solutions. Our team will fully support customers in the use of the disc granulation production line to ensure its smooth operation and achieve the expected production goals.

We are well aware that high-quality organic fertilizers can not only improve the yield and quality of durian, but also promote soil health and ecological balance. In the future, we look forward to working with YES Fertilizer Company to jointly promote the development of sustainable agriculture and create value for more farmers. At the same time, we also hope that this production line can bring economic and environmental benefits to more farmers and help the development of sustainable agriculture.

Related Recommendations:

what is process of fertilizer granulator

High efficiency and low cost fertilizer equipment

How to choose the right granulation process

Provide complete solutions fertilizer equipment supplier

Comparison between disc granulator and roller press granulator

What machine to make fertilizer

Industrial Commercial Composting Equipment Revolutionizing Fertilizer Production