Calcium chloride granulation plant — Fertilizer production process

2024-10-31What is calcium chloride?

Calcium chloride (CaCl₂) is an inorganic salt that can provide plants with calcium, an important nutrient element. It can improve the ability to resist pests and diseases, improve the quality of fruits, and neutralize the ability of acidic soil.

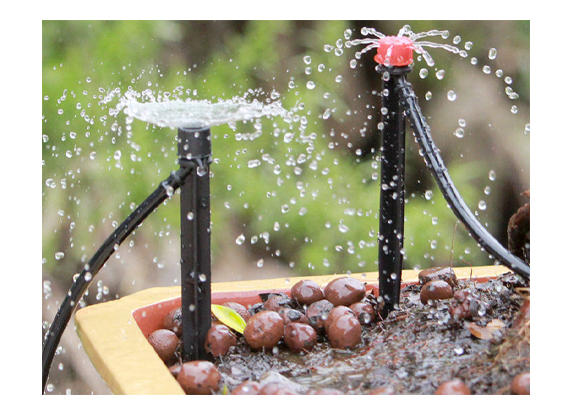

Calcium chloride is also soluble in water and has strong hygroscopicity. It can be used as foliar fertilizer or water-soluble fertilizer to spray on plant leaves or water the roots to increase the absorption rate of plants.

Calcium chloride granulation process

Calcium chloride is relatively stable at room temperature, and a double-roll extrusion granulator is usually used.

This granulator can use a dry granulation process at room temperature to form oblate granules in one extrusion. This greatly improves production efficiency. The finished granules are hard and do not require drying and cooling treatment, which reduces energy consumption and is more cost-effective.

Factors affecting the granulation process of calcium chloride

1. Environmental humidity

Calcium chloride has strong hygroscopicity, which may cause the material to absorb too much water before granulation, affecting the granulation effect. The environmental humidity and climate need to be controlled.

2. Agglomeration phenomenon

During the storage of ton-bag powdered calcium chloride, large lumps will appear due to problems such as humidity in the environment. I suggest using a compound fertilizer crusher to help you obtain a finer raw material powder.

Calcium chloride granulation plant: fertilizer granule production line

A complete calcium chloride production line plant usually includes batching, crushing, mixing, granulation, screening, packaging and other fertilizer production processes.

1. Batching machine: equipped with automatic batching system, multi-bin weighing and metering, remote monitoring, and real-time printing of reports. This makes fertilizer production more accurate and intelligent.

2. Crusher andmixer: Crusher and mixer are both used to make the nutrient distribution of raw materials more uniform and achieve the ideal particle size. This is crucial for the subsequent production of high-quality granular fertilizers.

3. Granulation: Roller extrusion granulator is a good choice. It will help you get uniform and hard fertilizer granules, providing strong help for fertilizer sales.

4. Screening machine: If you want to get high-quality potassium chloride granular fertilizer, a screening machine will help you filter out the dust in the finished granules. The dusty raw materials can be transported to the granulation link by a belt conveyor for re-granulation.

5. Packaging machine: Automatically package, weigh and seal the finished granules. Ensure sealing and moisture-proof for subsequent transportation and storage.

Calcium chloride production plants can efficiently produce high-quality calcium chloride to meet market demand through reasonable process flow, equipment configuration and strict quality control. At the same time, paying attention to environmental protection and sustainable development is an important development direction for modern production plants.

Related content:

Phosphate compound fertilizer granulation process

Industrial And Agricultural Urea 46 Fertilizer Granulator Machine

Slow-release fertilizer granulation process

How to process potassium chloride into fertilizer granules

How to produce organic fertilizer and compound fertilizer granules

Granular water-soluble fertilizer production process

How to choose the right granulation process

Comparison between disc granulator and roller press granulator