Organic fertilizer compost turning machine and production process

2024-07-29Composting, as a transmission biological treatment technology, is moving towards mechanization and commercialization after years of development and improvement.

Among the composting treatment methods, biological treatment is a method that has been studied more in recent years, among which aerobic fermentation is the main method. This method has the characteristics of low cost, strong life activity of fermentation products, high organic fertilizer efficiency, and easy promotion while achieving the purpose of deodorization and sterilization.

Fermentation Composting Method of Organic Fertilizer Composting Equipment

· Crawler compost turner - flat bottom pile fermentation method

Pile the prepared organic fertilizer raw materials into a long pile with a width of 2m and a height of 1.5m, and stack them according to the temperature.

Pile the prepared organic fertilizer raw materials into a long pile with a width of 2m and a height of 1.5m, and stack them according to the temperature.

The crawler compost turner can be driven to the composting area and can be turned indoors or outdoors.

· Wheel type compost turner - groove-type organic fertilizer compost turning method

Generally, the organic fertilizer compost groove is 5~10m long, 6m wide, and 2m high. It is composed of several compost grooves arranged and placed in a closed or semi-closed fermentation room. A 1.5mm ventilation pipe is buried at the bottom of each tank. After the material is filled, the high-pressure blower is forced to ventilate regularly to keep the groove well-ventilated. It promotes the rapid reproduction of aerobic microorganisms.

Wheel compost turner has large output and high turning efficiency, and is suitable for large-scale organic composting treatment.

· Horizontal fermentation tank - organic fertilizer fermentation method of the fermentation tank

The organic fertilizer fermentation tank is a rectangular tank with a layered structure inside. Different capacities can be selected according to the output. The harmless treatment can be completed in 10 hours, and the temperature can be adjusted to a constant temperature of 60-100℃. Sealed fermentation, no air pollution.

Common Raw Materials for Composting

Livestock manure Poultry manure Cow dung Sheep dung Horse dung Crop straw and residues Cake meal | Algae and other aquatic plants Silt and sludge Kitchen waste Wood chips and shavings Fly ash Bark | Municipal sludge Paper sludge Sugarcane and beet filter mud End products of manure and urea composting Fruit and vegetable waste Food processing waste Peat | Charcoal Lime Slaughterhouse waste Rice bran and husks Wheat bran Peanut shells |

Generally speaking, the transportation distance of composting raw materials does not exceed 100km, so composting plants should try to find suitable organic raw materials locally.

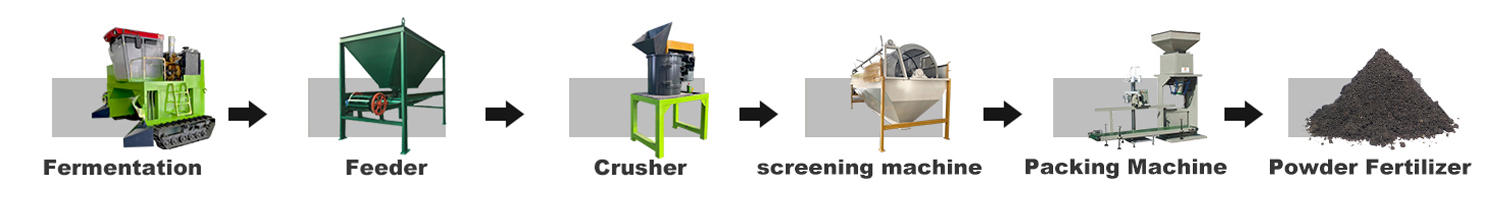

Organic Fertilizer Composting Production Line

Organic fertilizer composting production line refers to a complete set of process flow for producing organic fertilizer, which usually includes raw material processing, fermentation composting, composting fermentation, crushing, mixing, granulation, packaging and other links. The following is an introduction to the general workflow of organic fertilizer composting production line:

1. Raw material processing equipment: The raw materials of organic fertilizer can include organic materials such as crop straw, livestock and poultry manure, and discarded vegetable leaves. These raw materials are processed (such as crushing, soaking, etc.) as raw materials for organic fertilizer.

2. Organic fertilizer compost turning machine: Regularly turn and stir the compost pile to ensure that the raw materials in the compost are fully exposed to the air and have uniform humidity to promote fermentation.

3. Crusher: Crush the fermented organic compost to make it more delicate and uniform for subsequent processing.

4. Mixing: Organic fertilizers of different components are mixed according to the proportion requirements to obtain a balanced nutrient content.

5. Granulation: The mixed organic fertilizer is granulated by a granulator and processed into regular granules for easy transportation and application.

6. Packaging: Finally, the organic fertilizer is packaged for easy storage, transportation and sales.

The workflow of the organic fertilizer composting production line can be adjusted and optimized according to the production scale and technical requirements. At the same time, it is also necessary to comply with environmental protection standards to ensure that the production process is hygienic and safe, and complies with relevant laws and regulations.

Simple powdered organic fertilizer production line