How to process potassium chloride into fertilizer granules

2024-06-14Application of potassium chloride in fertilizers

Potassium chloride is known as potash fertilizer and is one of the main nutrients necessary for plant growth. Today, more than 30 million tons of potassium are produced worldwide each year.

Potassium chloride (KCI) can effectively promote plant photosynthesis and improve the disease and cold resistance of plants. It can regulate soil pH and improve soil structure to a certain extent and has the effect of increasing crop yield and improving quality. It is commonly used to make various potassium-containing fertilizers, such as potassium chloride fertilizers, compound potassium fertilizers, etc., to provide the potassium elements required by plants. Potassium chloride usually exists in the form of white crystalline solids and is easily soluble in water. It is widely used in the production of water-soluble fertilizer granules, compound fertilizer granules, inorganic fertilizer granules, slow-release fertilizer granules, etc.

Production process of potassium chloride fertilizer granulator

The double roller extrusion fertilizer granulator machine adopts a dry granulation process, which can be used to convert powdered or blocky raw materials into granular materials.

The double roller extrusion fertilizer granulator machine is used to produce potassium chloride granules, and no additives are required in the granulation process. The finished granules after granulation do not need to be dried and cooled, which reduces energy consumption.

You can control the size, shape, and density of the granules by adjusting the size and speed of the double-roll die.

The double roller press fertilizer granulator machine can realize continuous granulation work, and granules can be formed in one extrusion. It has the characteristics of high efficiency, wear resistance, and corrosion resistance.

Potassium chloride has high solubility in water, which makes it difficult to achieve the ideal granulation effect during wet granulation. When producing potassium chloride fertilizer granules, it is necessary to control the particle size distribution and uniformity of the granules to ensure the uniformity and absorption rate of plant fertilization. We have developed a complete potassium chloride granulator fertilizer production line to help you solve the fertilizer production problem.

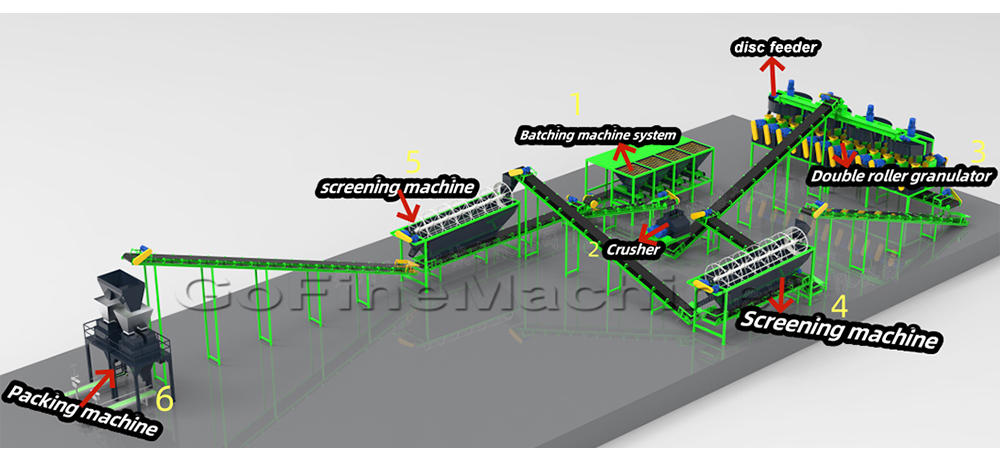

Potassium chloride fertilizer granulator production line

1. Automatic batching system:multiple raw materials are mixed according to a certain ratio, and data can be monitored remotely.

2. Crusher: crush the fertilizer raw materials to the ideal particle size.

3. Mixer:fully mix the materials to ensure the uniformity of nutrients.

4. Fertilizer granulator machine: the double roller extrusion granulator adopts a dry granulation method, low energy consumption, and high efficiency.

5. Packaging machine: the granulated potassium chloride fertilizer granules can be directly weighed and packaged.

6. Robotic palletizer: transport and palletize the packaged bagged fertilizer according to certain rules to reduce labor costs.

For more fertilizer granulation production problems, please contact us!

Gofine is committed to tailoring the most suitable solution for you.