High-quality chicken manure organic fertilizer pellet production equipment and technology

2025-12-26Producing premium quality chicken manure fertilizer requires more than basic processing—it demands specialized equipment designed specifically for organic materials' unique characteristics. While many manufacturers focus on volume, discerning buyers seek fertilizers with consistent quality, enhanced durability, and specialized properties that command premium prices. Our range of specialized fertilizer production equipment addresses these exacting requirements, transforming composted chicken manure into superior, market-ready products.

Advanced Granulation Technology for Organic Materials

Dry Granulation: The Precision Approach

Our dry fertilizer granulation systems offer distinct advantages for quality-conscious producers:

Material Preservation: Low-temperature processing maintains beneficial microorganisms

Nutrient Retention: Minimizes nitrogen loss during pellet formation

Density Control: Produces pellets with specific bulk density for different applications

Formula Flexibility: Easily incorporates additional nutrients or amendments

Unlike wet granulation methods that require extensive drying, our dry systems process materials at optimal moisture levels (12-18%), resulting in pellets with excellent structural integrity and nutrient preservation.

Specialized Drum Granulator Features

Our rotary drum granulator for organic materials includes enhancements specifically for chicken manure:

Gentle Tumbling Action: Specially designed lifters prevent excessive pellet breakdown

Moisture Control Systems: Precise water addition for optimal pellet formation

Anti-adhesion Design: Special drum lining prevents material buildup

Variable Speed Control: Adjustable rotation for different pellet sizes (2-6mm)

Value-Adding Finishing Equipment

The Polishing Difference

A fertilizer polisher represents the crucial difference between standard and premium pellets:

Surface Refinement: Removes sharp edges and surface imperfections

Dust Reduction: Eliminates surface fines that create dust during handling

Improved Flow: Creates uniform spherical shapes for better equipment flow

Aesthetic Enhancement: Produces professional, market-attractive appearance

Polishing typically improves pellet durability by 25-40% while reducing dust generation by up to 70%, directly impacting customer satisfaction and market acceptance.

Coating Technology for Enhanced Performance

Our fertilizer coating machine systems apply various treatments to enhance product value:

Dust Control Coatings: Mineral oils or specialized polymers that minimize dust

Moisture Barriers: Protective coatings for humid climate markets

Nutrient Enhancement: Coatings containing micronutrients or beneficial microbes

Slow-Release Formulations: Polymer coatings for controlled nutrient release

Quality Control and Testing Systems

Premium production requires rigorous quality assurance:

| Quality Parameter | Testing Method | Target Range | Equipment Used |

|---|---|---|---|

| Pellet Hardness | Compression testing | 8-12 N | Digital hardness tester |

| Moisture Content | Moisture analyzer | 10-15% | Infrared moisture meter |

| Pellet Uniformity | Sieve analysis | 85-90% in target size | Vibratory sieving system |

| Dust Content | Elutriation testing | <2% | Dust analysis chamber |

| Disintegration Rate | Water immersion test | 15-30 minutes | Disintegration tester |

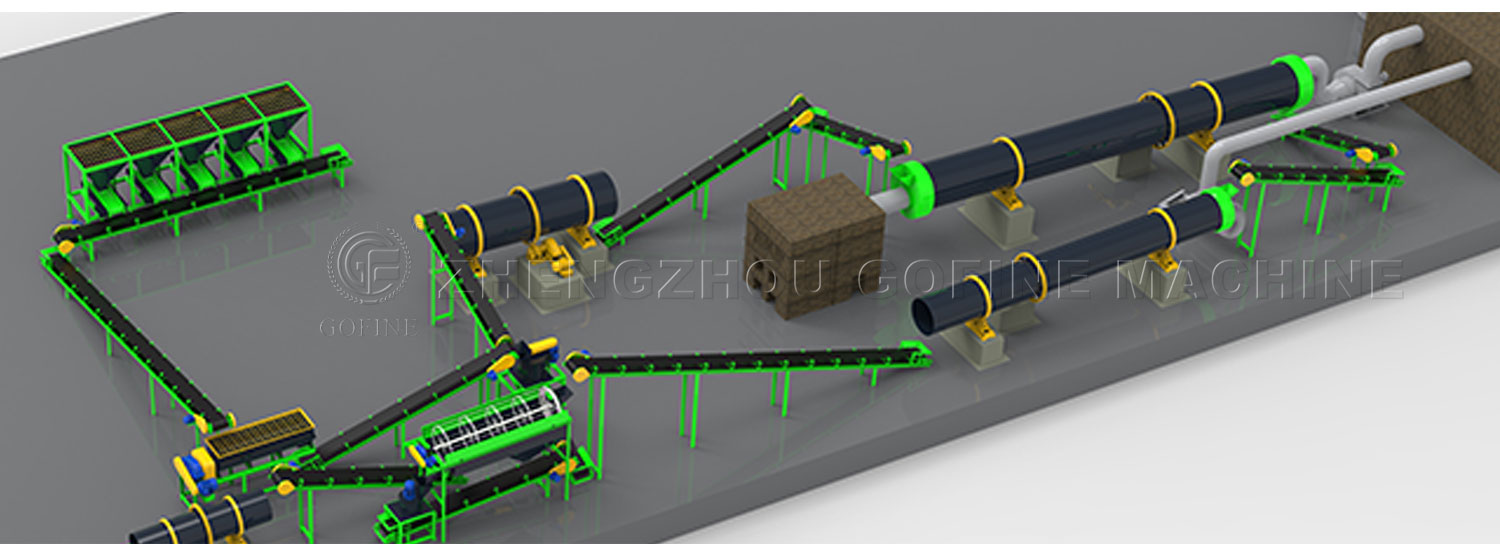

Production Line Integration

A complete premium fertilizer line integrates multiple specialized components:

Pre-Granulation Processing

Precision crushing to uniform particle size

Moisture adjustment systems

Automated batching for formula consistency

Granulation Stage

Controlled feeding to granulator

Real-time moisture monitoring

Temperature control during processing

Finishing Operations

Multi-stage screening and recycling

Sequential polishing and coating

Final quality verification

Packaging Systems

Automated weighing and bagging

Metal detection and quality control

Palletizing and warehouse management

Technical Advantages for Market Competitiveness

Implementing specialized equipment provides measurable market advantages:

Price Premium: Quality pellets command 20-40% higher prices than unprocessed material

Market Access: Meets specifications for premium organic markets and exports

Brand Development: Consistent quality supports brand building and customer loyalty

Operational Efficiency: Reduced returns and customer complaints

Customization for Specific Market Needs

We offer equipment customization based on target markets:

Home Garden Market: Small pellets (2-3mm) with attractive packaging

Commercial Agriculture: Durable pellets (4-6mm) for mechanical spreading

Export Markets: Enhanced durability for shipping and tropical climates

Specialty Applications: Custom coatings for specific crops or soil conditions

Conclusion: Investing in Quality for Long-Term Success

The organic fertilizer market increasingly rewards quality over quantity. By investing in specialized fertilizer pellets machines, advanced coating systems, and precision polishing equipment, chicken manure processors can transform their product from a commodity to a premium brand. Our equipment provides the technological foundation for this transformation, offering the control, consistency, and quality enhancement capabilities needed to compete in today's demanding organic fertilizer markets.

The return on investment comes not just from equipment efficiency, but from the ability to access higher-value market segments, build brand equity, and establish long-term customer relationships based on product reliability and performance excellence.