From Waste to Organic Fertilizer Dairy Manure Compost Plant

2026-01-12The journey of transforming raw cow dung into premium, packaged cow manure fertilizer represents one of agriculture's most valuable circular economies. For entrepreneurs and agricultural cooperatives, establishing an organic fertilizer plant is a strategic move that turns a disposal problem into a significant revenue stream. This article outlines the essential stages, from initial composting dairy manure to final bagging, and the organic fertilizer machines required to build a successful and profitable operation, be it a dedicated manure fertilizer plant or an integrated compound fertilizer plant.

Phase 1: The Foundation - Efficient Composting & Fermentation

The heart of any organic plant is a robust composting system. This is where waste is stabilized and sanitized.

-

The Process of How to Compost: Effective composting dairy manure follows defined steps of compost: forming windrows, monitoring temperature and moisture, and regular turning. This aerobic fermentation process is accelerated and managed by specialized equipment.

-

Core Equipment - Compost Turners: For a large scale composting machine setup, a crawler type compost turner is ideal for handling massive volumes. For more controlled, high-efficiency operations common in a bio fertilizer plant, a groove type compost turner system is superior. For medium sized composting equipment needs, a versatile moving type compost turner or wheel type compost machine provides the perfect balance.

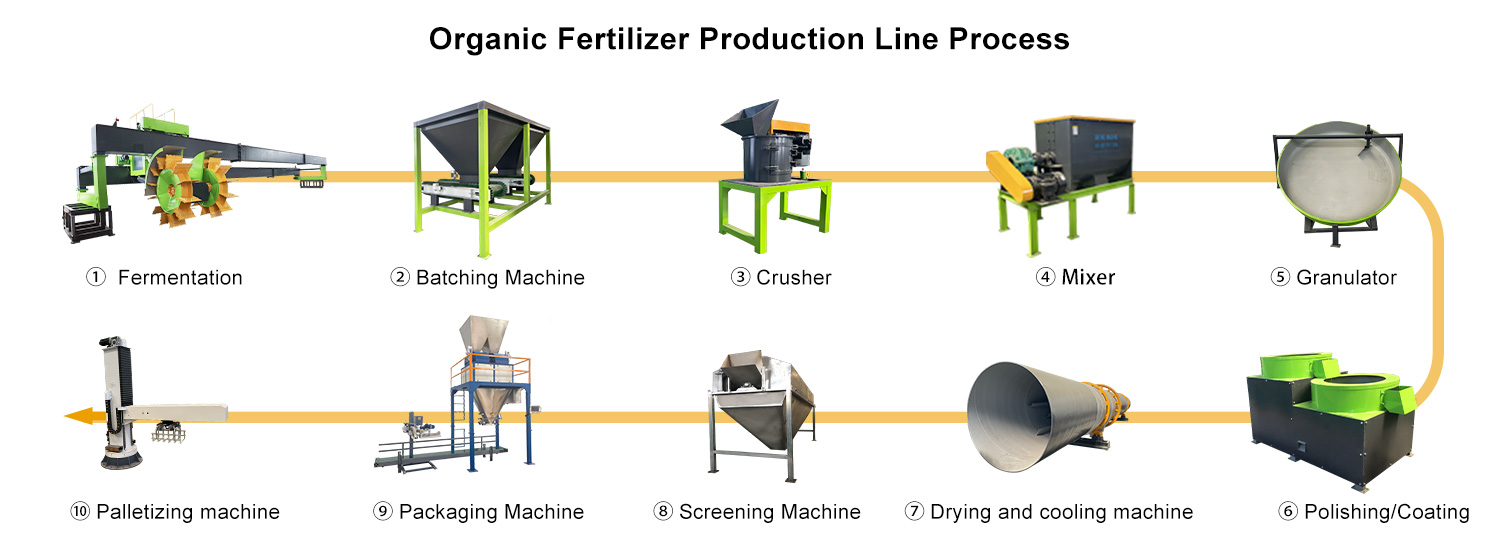

Phase 2: Processing & Refinement - Creating a Uniform Product

Once fully fermented, the compost must be refined into a consistent product ready for the market.

-

Crushing & Screening: The compost is passed through crushers and screens to achieve a fine, uniform particle size. This is crucial for the next stage of granulation or for selling high-quality powder fertilizer.

-

Granulation (For Premium Products): To produce granular fertilizer that is easier to store, transport, and apply, a granulation system (such as a disc or drum granulator) is used. This is a key differentiator for a compound plant producing blended NPK fertilizers.

-

Drying & Cooling: Fresh granules contain moisture and must be dried and cooled to achieve hardness and stability for long-term storage.

Phase 3: Finishing & Market Readiness - Adding Value

The final phase prepares the fertilizer for sale and maximizes its market value.

-

Coating & Packaging: A coating drum can apply anti-caking agents. The product then moves to the fertilizer packaging plant stage, where automated weigh-filling and sewing machines bag the final product professionally.

-

Quality Control: A reputable organic fertilizer plant will have a lab to test nutrient content (N-P-K), moisture, and organic matter to ensure consistent quality and meet regulatory standards.

Designing Your Plant: Scale and Integration

The design of your plant depends on your raw material input and target market.

-

Dedicated Cow Dung Fertilizer Plant: Focuses on processing manure from specific livestock operations into organic fertilizer.

-

Integrated Compound Plant: Combines composted manure with mineral nutrients (like N, P, K) to produce standardized compound fertilizers with specific nutrient ratios.

-

Modular Bio Fertilizer Plant: Can include inoculation with beneficial microbes after granulation to create enhanced bio fertilizer.

Conclusion: A Blueprint for Success

Building a successful compost production plant is a significant but rewarding investment. The key is to view it as an integrated system where each phase—fermentation with the right compost turner, processing, and packaging—is seamlessly connected. By selecting the appropriate fermentation compost equipment for your scale, whether it's for a small scale fermentation setup or a full industrial compound fertilizer plant, you create an efficient operation that converts dairy manure compost into a trusted, market-ready product. This not only solves an environmental challenge but also establishes a sustainable and profitable agricultural business.