News

Maximize your ROI with our durable Potassium Sulfate Fertilizer Production Line. Professional EPC services and global installation support available.

Discover the technical advantages of using a rotary drum granulator in a bulk blending fertilizer line. Learn how its gentle tumbling action ensures superior mix uniformity, preserves granule integrity, and prevents segregation.

Explore the dry SSP pelletizing process using an Extrusion Granulator. This article details the compact production line, its energy-saving advantages, and the continuous process for producing high-density SSP granules without drying.

Master your compost turner operation. Learn how to control moisture, aeration, and C/N ratio to accelerate fermentation and produce higher quality compost efficiently with our expert tips.

Learn how Semi-Wet Crushers and Chain Crushers transform raw chicken manure and cow dung into uniform powder for efficient granulation or direct sale.

The journey of transforming rawcow dunginto premium, packagedcow manure fertilizerrepresents one of agriculture's most valuable circular economies. For entrepreneurs and agricultural cooperatives, establishing anorganic fertilizer plantis a strategic move that

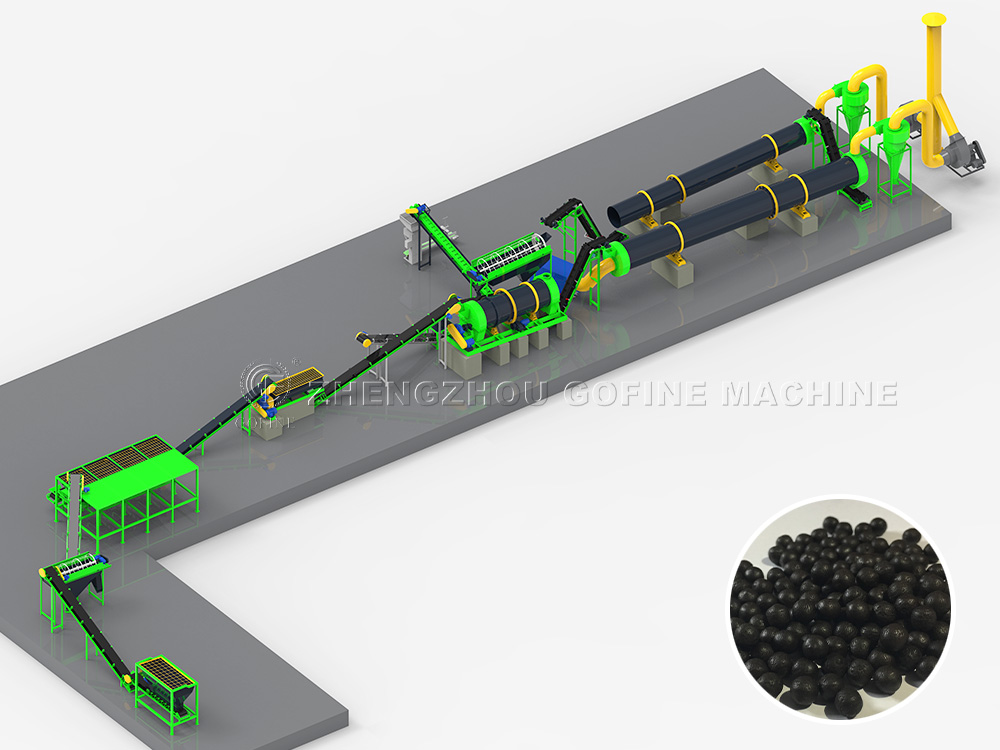

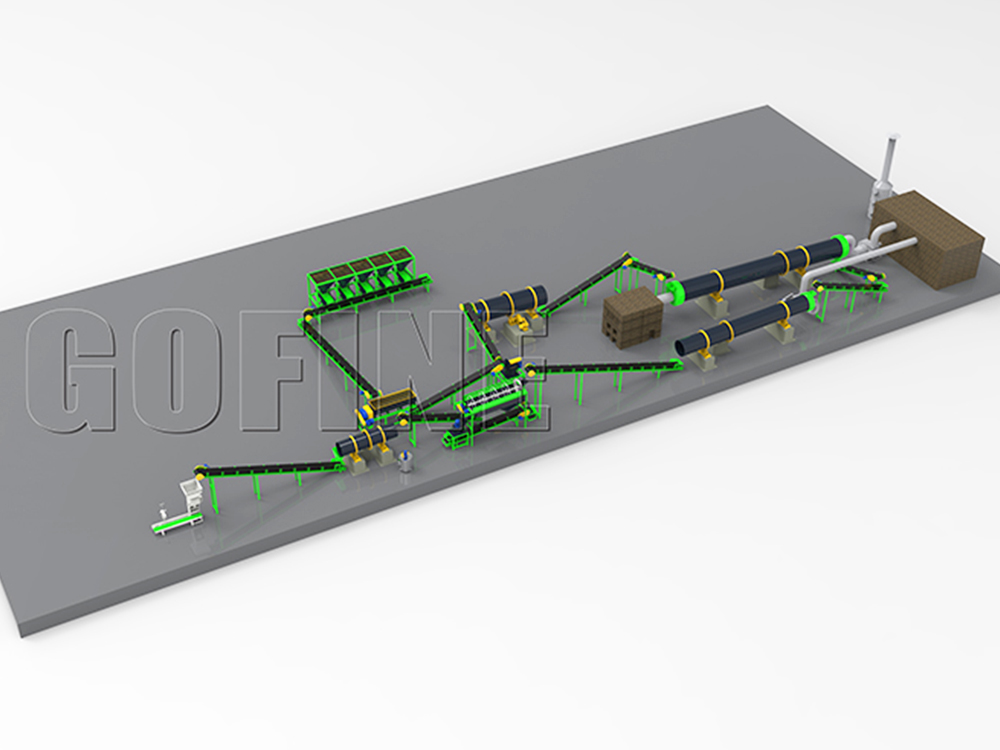

Your pellet machine is just one part. Discover the complete production line for organic fertilizer pellets—from composting & crushing to drying & screening. Learn how to build a synchronized system for consistent quality.

Transformingchicken manurefrom a waste liability into anorganic fertilizerasset is a sound business decision. However, its success depends on careful financial and strategic planning. Prospective investors most frequently ask: “What is thechicken waste processing machi

Learn about specialized equipment for producing high-quality chicken manure fertilizer pellets, including advanced granulators, polishers, and coating machines for market-ready organic fertilizer.

Discover how dual-fermentation ensures complete pathogen removal, stable nutrients, and an eco-friendly process for market advantage.