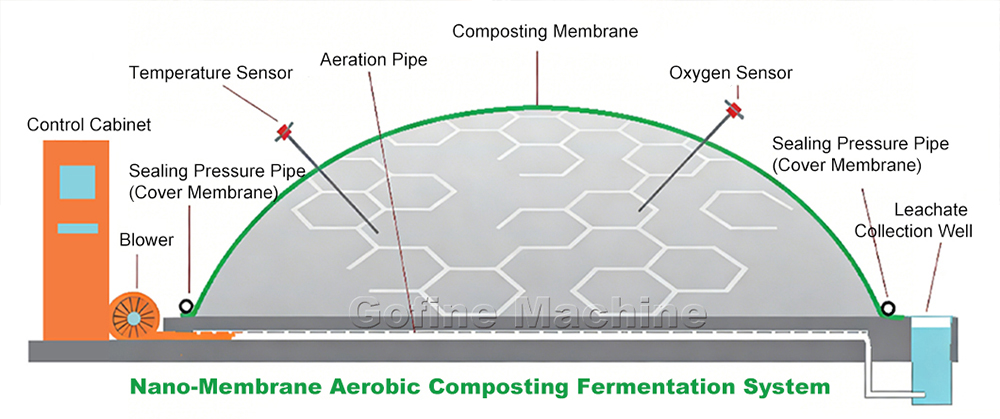

E-PTFE Membrane Covered Aerobic Composting System

- Information

Product Overview

Our Membrane Covered Aerobic Composting System represents a revolutionary leap in organic waste processing technology. This advanced, enclosed system utilizes a proprietary functional membrane to create an optimized micro-environment for accelerated aerobic fermentation. Designed for municipal sludge, livestock manure, agricultural waste, and industrial organic by-products, it delivers faster composting cycles, near-total odor containment, and superior compost quality—all with minimal energy input and operational complexity. It is the ideal turnkey solution for operations prioritizing environmental compliance, space efficiency, and consistent, high-volume output of stable compost or organic fertilizer feedstock.

Core Advantages & Problem Solving

1. Eliminates Odor & Enhances Community Compliance

Solves: Nuisance odors and community complaints from open windrows.

How: The semi-permeable membrane acts as a highly effective physical and molecular barrier. It contains malodorous gases (ammonia, H₂S) and volatile organic compounds (VOCs) within the pile while allowing water vapor to escape. This enables operation in sensitive or populated areas where traditional composting is not feasible.

2. Accelerates Fermentation & Boosts Throughput

Solves: Long, weather-dependent composting cycles (often 8-12 weeks).

How: The system maintains optimal and uniform temperature (>55°C), moisture (50-60%), and oxygen concentration (10-15%) throughout the pile. This creates ideal conditions for thermophilic microbes, slashing the primary fermentation period to just 3-4 weeks and dramatically increasing annual processing capacity.

3. Optimizes Process Control with Minimal Labor

Solves: Inconsistent results and high labor costs from manual turning and monitoring.

How: Integrated positive aeration from the floor ensures uniform oxygen distribution without frequent turning. Smart sensors monitor core parameters in real-time, enabling automated or semi-automated process adjustment. Labor is reduced primarily to loading and unloading.

4. Protects Against Weather & Saves Resources

Solves: Loss of efficiency and product quality due to rain, snow, or excessive evaporation.

How: The membrane cover sheds precipitation, eliminating leachate runoff and preventing piles from becoming waterlogged. It also retains heat and moisture, reducing the need for rewetting and ensuring consistent process conditions year-round, regardless of external weather.

5. Produces Higher Quality, More Stable End Product

Solves: Inconsistent or immature compost that may contain pathogens or weed seeds.

How: Sustained, uniform high temperatures ensure effective pathogen eradication and weed seed destruction. The controlled aerobic process promotes thorough humification, resulting in a more stable, mature, and consistent compost ideal for agricultural or horticultural use.

Application

Municipal Sector: Sludge/biosolids stabilization from wastewater treatment plants.

Livestock Operations: Centralized treatment of manure from dairy, poultry, and swine farms.

Agriculture & Horticulture: On-farm composting of crop residues and production of high-quality soil amendments.

Food Processing & Organics Recycling: Treatment of green waste, food scraps, and other source-separated organics.

Remediation Projects: Treatment of contaminated soils via bio-remediation.

Work process

Pre-mixing and Stacking: Pre-treated organic waste (with adjusted carbon-to-nitrogen ratio and moisture content) is piled onto a concrete platform equipped with a built-in aeration network, forming long, trapezoidal stacks.

Membrane Covering: A proprietary functional membrane cover is laid over the entire stack, creating a semi-enclosed environment. Our roll-film covering machine can be used in conjunction with this process, improving membrane covering efficiency and simultaneously turning the material to enhance composting efficiency.

Controlled Aerobic Fermentation: Blowers deliver air through underground aeration pipes based on preset oxygen/temperature thresholds. The membrane cover regulates gas exchange – releasing carbon dioxide and water vapor while effectively controlling odors.

Monitoring and Adjustment: The stacks are equipped with a temperature control system. Operators can remotely monitor the fermentation process and adjust the aeration cycle as needed without removing the membrane cover.

Maturation and Unloading: After the high-temperature aerobic fermentation stage (typically 21-28 days), the nano-membrane cover is removed using a roll-film machine. The stabilized material is transferred to a maturation area for final curing, followed by screening and application.

Technical Parameters

Product nam | Membrane Covering System |

Production process | Single-batch composting with intermittent micro-aeration |

Production environment | Closed system, odorless, open-air, environmentally friendly |

Safety effect | Maximum temperature reaches 80℃, effectively killing pathogens, insect eggs, and weed seeds; excellent results, thorough fermentation, nitrogen fixation effect, high total nutrients, and high degree of maturity |

Production time | 25 days |

Operationality | Very simple |

Advantages | Simple structure, no maintenance required, lowest production energy consumption, no environmental pressure, and highest nutrient content |

Product photos

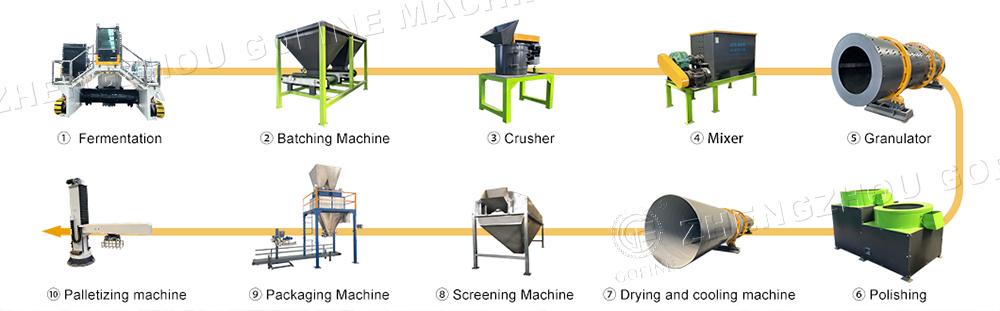

Applications in Organic Fertilizer/Soil Conditioner Production Lines

This system is the core primary fermentation equipment in modern organic waste resource utilization facilities. It reliably and efficiently converts untreated waste into organic fertilizer. This can then proceed to post-processing stages such as drying, crushing, screening, adding auxiliary materials and mixing, and granulation, ultimately producing commercial-grade organic fertilizers, soil conditioners, or growing media. Its controllable and rapid process ensures stable feeding to downstream equipment, thereby optimizing the efficiency and product quality of the entire production line.

Upgrade to a cleaner, faster, and smarter composting solution. Contact us to design a Membrane Covered Composting System tailored to your specific waste stream and capacity requirements.