Fully hydraulic crawler-type compost turning machine

- Information

Overview

Introducing our high-performance Fully Hydraulic Crawler-Type Compost Turner, engineered to revolutionize your organic waste processing and composting operations. This robust machine is designed for large-scale, factory-style ground windrow fermentation, offering unparalleled efficiency in bio-organic fertilizer production. It is the ideal solution for transforming a wide range of organic materials—including livestock manure, agricultural waste, sludge, and industrial by-products—into high-quality, stable compost or organic fertilizer. Combining intelligent design with powerful performance, it significantly accelerates the fermentation cycle while ensuring optimal aeration, homogenization, and consistent compost quality.

Key Features & Advantages

1. Boost Output & Slash Costs

Process 500-1600 m³ per hour—dramatically accelerating your production cycle. Advanced engineering cuts fuel consumption by 33-50% versus competitors, directly lowering your cost per ton.

2. Achieve Perfect, Consistent Compost

Our high-torque drum reaches the very bottom of the windrow every time, eliminating anaerobic pockets. It thoroughly blends, fluffs, and oxygenates for faster, more uniform fermentation and higher-quality end product.

3. Operate with Unmatched Ease

Command all major functions from a panoramic cabin using a single, intuitive lever. Hydraulic controls provide smooth, responsive operation, reducing operator fatigue and training time.

4. Adapt to Any Pile with Precision

Hydraulically adjust the drum from 1.8 to 2 meters to handle varying windrow sizes and material conditions perfectly, ensuring optimal results across all your feedstocks.

5. Maximize Yard Space & Uptime

The integrated track cleaner automatically keeps undercarriages debris-free, enabling tight windrow placement to save space. Its robust, low-maintenance design ensures maximum machine availability for your operations.

Working Process

Powered by a high-efficiency diesel engine, the machine utilizes a fully hydraulic transmission system to deliver power to all moving parts. The operator drives the machine along the windrow. The heavy-duty, alloy-tipped turning blades on the rotating drum efficiently lift, cut, and fling the material backwards. This action blends the raw and decomposed materials, breaks up clumps, introduces crucial oxygen into the core of the pile, releases heat and gases, and re-forms the windrow into a loose, porous structure ideal for microbial activity. The simultaneous operation of the crawler cleaner ensures the undercarriage remains clear of debris.

Application Scope

This versatile turner is essential for various industries involved in organic waste management and recycling:

Organic Fertilizer Plants: Core equipment for efficient compost production from diverse feedstocks.

Livestock & Poultry Farms: For in-situ management and composting of manure and bedding.

Wastewater Treatment Plants: Processing sludge into stabilized biosolids for land application.

Agro-Industrial Facilities: Handling by-products like crop residues (straw), distillery grains (brewery/spent grains), oil cakes, and food processing waste.

Large-Scale Nursery & Growing Media Producers: Manufacturing compost-based potting mixes and substrates.

Composite Fertilizer/Blending Plants: Preparing organic base materials for further processing.

Technical Parameters

| Windrow width | ≤5.1 meters |

| Windrow height | ≤2.1 meters, hydraulically adjustable windrowing shaft height |

| Row spacing of piled material | 0.8-1 meter |

Drum diameter | ≤1.1 meters |

Power/Horsepower | 117-247 kW / 160-336 horsepower |

Rotation speed | 2400-2100 r/min |

Traveling speed | 5-10 meters/minute |

| Speed adjustment direction | Speed can be adjusted according to the composting process to maximize windrowing efficiency and adapt to the raw material condition, maximizing the looseness and permeability of the raw materials. |

| Equipment features | Turbocharged engine, water spraying device, adjustable steering, and on-board air conditioning. |

Product details

Role in the Fertilizer Production Line

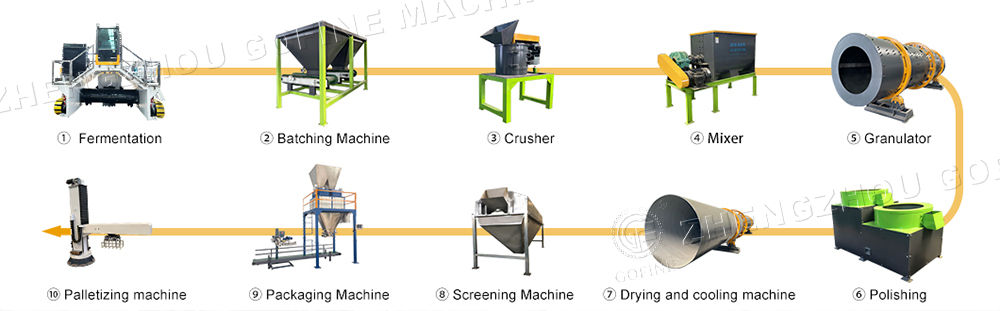

In a complete organic or bio-organic fertilizer production line, the Fully Hydraulic Crawler Turner plays a critical role in the primary fermentation stage. It is responsible for the active, high-volume composting phase where raw materials are transformed into stabilized organic matter. Its high turnover capacity ensures rapid processing of large windrows, reducing the overall fermentation cycle time. By providing consistent and thorough aeration, it maintains ideal thermophilic conditions (up to ~65°C), facilitating pathogen reduction and efficient decomposition. The output is a uniformly composted material that is ready for secondary fermentation, drying, crushing, screening, granulation (if needed), and final packaging. Its efficiency directly impacts the throughput, quality consistency, and operational cost of the entire fertilizer manufacturing process.

Upgrade your composting operations with this powerful, smart, and economical solution. Contact us for more detailed specifications and to discuss how this turner can optimize your organic fertilizer production line.