-

Home >> Solutions >> Design and diagram

Manure fertilizer production solutions

Livestock and poultry manure contains rich organic matter and a variety of nutrients needed by crops, such as nitrogen, phosphorus, potassium, etc. It also provides medium and trace nutrients such as calcium, magnesium, sulfur, zinc, iron, manganese, and boron.

With the development of animal husbandry, global agricultural waste output has gradually increased. Among them, livestock and poultry manure, crop straw waste, vegetable waste, township domestic waste and human feces, and cakes account for the highest proportion of agricultural waste emissions. A large amount of livestock manure is directly discharged into the agricultural ecosystem, which will cause extreme deterioration of the ecological environment.

How to effectively handle and dispose of livestock and poultry manure to make it harmless, reduced, and resourceful is an issue we are currently paying attention to.

Effect of manure on organic fertilizer

Understanding the characteristics of different poultry manures is an important aid in producing high-quality organic fertilizers.

▶ Pig Manure

The main components of pig manure are cellulose and hemicellulose and also contain protein, fat, organic acids, and various inorganic salts.

The organic fertilizer formed after composting has a higher humus content. After application, it can increase the fertilizer and water retention properties of the soil. Organic composted pig manure can form a large amount of organic humus and wax, which has a certain effect on plant drought resistance.

| Variety | Crude organic fertilizer | N | P | K | Ca | Mg | S |

| Pig manure | 183 | 5.5 | 2.4 | 2.9 | 4.9 | 2.2 | 1.0 |

| Pig urine | 8 | 1.7 | 0.2 | 1.6 | 0.1 | 0.1 | 0.2 |

| Pig feces and urine | 38 | 24 | 0.7 | 1.7 | 3.0 | 1.0 | 0.7 |

▶ Horse Manure

Horses like to chew roughage that is difficult to digest. Horse manure contains more cellulose and hemicellulose.

Horse manure is prone to high temperatures during the production process of organic fertilizer compost. It is a hot fertilizer and is not recommended to be applied alone.

If you want to speed up the decomposition of manure, you can add an appropriate amount of horse manure during high-temperature organic composting, which can also preserve the nitrogen in the horse manure.

▶ Cow Dung

Cow dung has a fine texture, high water content and poor air permeability. Moreover, organic matter is difficult to decompose, matures slowly, and the compost fermentation temperature is low, so it is a cold fertilizer.

| Variety | Crude organic fertilizer | N | P | K | Ca | Mg | S |

| Cow dung | 149 | 3.8 | 1 | 2.3 | 18.4 | 4.7 | 3.1 |

| Cow urine | 28 | 5 | 0.17 | 9.1 | 0.6 | 0.5 | 0.4 |

| cow dung and urine | 78 | 3.5 | 0.82 | 4.2 | 4 | 1.0 | 0.7 |

▶ Poultry Manure

Poultry manure includes chicken manure, duck manure, goose manure, etc. Poultry manure is a highly concentrated natural compound organic fertilizer.

The moisture content of fresh poultry manure is 51%~62%, the organic matter content is about 200g/kg, nitrogen is 5~10g/kg, and phosphorus is 2~4g/kg.

Potassium 5~7%, and also contains trace and medium elements such as copper, zinc, iron, manganese, calcium, and magnesium.

Solutions for Manure Organic Fertilizer Production

Organic Fertilizer Composting Machine

Organic fertilizer composting turner machine are suitable for medium and large enterprises that have quality requirements for fertilizers and want to stable and batch production of organic fertilizers.

Some gardeners like to compost in their own gardens. However, in the process of organic fertilizer compost production, you cannot accurately control key parameters such as temperature, humidity, and oxygen supply of the compost pile. This prevents you from getting better quality organic fertilizer quickly. Organic fertilizer composting equipment can help you solve this problem efficiently.

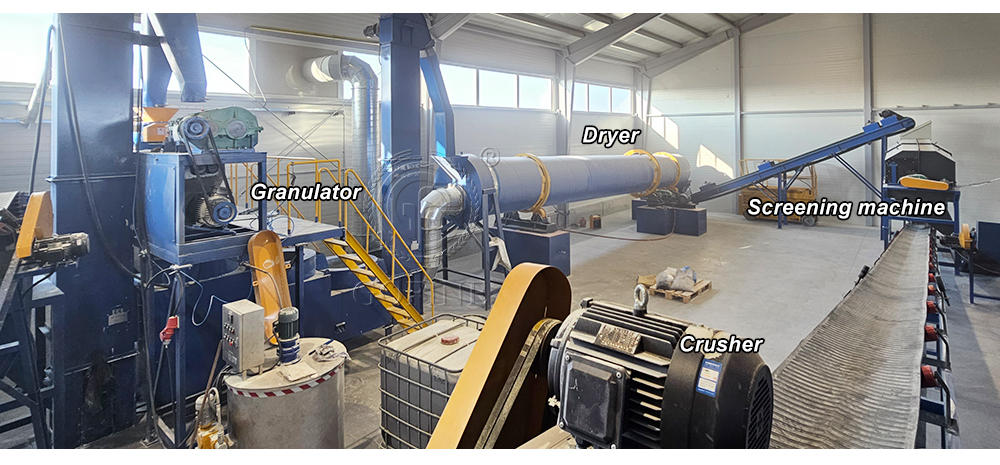

Organic Fertilizer Granule Production Equipment

When you already have a batch of powdered organic fertilizer, you can use a fertilizer granulator, which will help you quickly process the powdered organic fertilizer into granular organic fertilizer, which will greatly improve your economic benefits.

Making granular organic fertilizer can reduce fertilizer loss and volatilization, improve fertilizer utilization, reduce fertilizer dosage, and save costs. Granular organic fertilizer is small in size and high in density, making it easy to transport and store. By adjusting the process parameters of the fertilizer granulator, precise control of the composition of fertilizer particles can be achieved to meet the nutrient needs of different crops.

The fertilizer granulator has two granulation methods: wet granulation and dry granulation. For different outputs, we have corresponding fertilizer granulation equipment for you to choose from.

Organic Fertilizer Production Line

If you need to produce high-quality organic fertilizer on a large scale, I suggest you build a fertilizer production plant, which will be ideal for producing organic fertilizer. The organic fertilizer production line can effectively control the production formula and ensure that organic matter is efficiently converted into high-quality fertilizer.

A simple manure organic fertilizer production line includes compost fermentation equipment, a batching system, a crusher and mixer, a packaging machine, and other fertilizer machines.

Large-scale production can reduce production costs and improve economic benefits while supporting resource reuse and reducing environmental impact.

Based on your production needs and factory area, I will customize the best fertilizer production line solution for you.

Detailed one-stop purchasing introduction for fertilizer production lines. (Please click)