-

Home >> Solutions >> Design and diagram

Bentonite cat litter granulator production solution

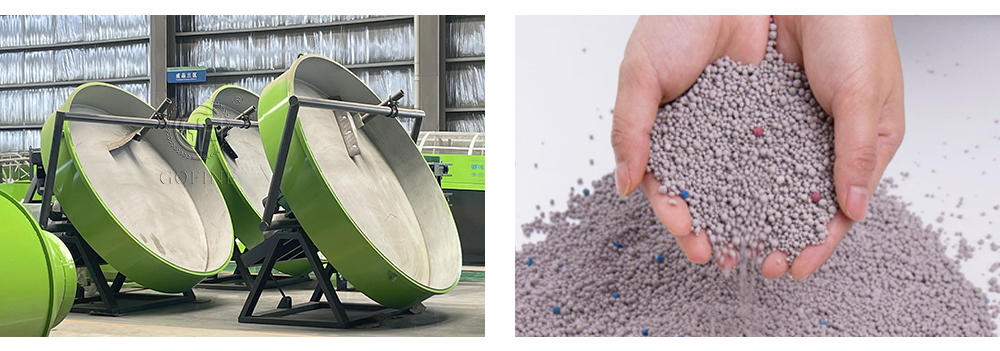

Bentonite cat litter is one of the important products used by pet owners to provide a comfortable and sanitary environment for their cats. However, in the production process of bentonite cat litter, how to efficiently produce uniform and well-agglomerated particles is an important technical challenge. In this regard, disc granulators and double roller press granulator are two commonly used granulation equipment, which play a key role in the production of bentonite cat litter granules.

A disc granulator is a granulation equipment suitable for granulation of various powdery and granular raw materials. In the production of bentonite cat litter granules, the disc granulator can evenly mix the raw materials by rotating the disc, and then form granules in the process of wet granulation. The disc granulator has the advantages of fast granulation speed, good granulation effect and good product forming. It is suitable for small production lines and scenes with high requirements for particle shape and size.

Double Roller Press Granulator

A double roller extrusion granulator is another common granulation equipment. Its principle is to extrude bentonite raw materials to form oblate cat litter granules. In the production of bentonite cat litter granules, the shape of the finished cat litter particles can be changed by adjusting the specifications and dimensions of the roller grinder. Because of the dry granulation method, there is no need for a drying process after granulation, which effectively saves energy consumption and reduces costs.

The double roller press granulator has the advantages of high production efficiency, controllable process, and high density of finished particles. It is suitable for large-scale production lines and scenarios with high requirements for particle shape and density.

The production process of bentonite cat litter granules usually includes raw material preparation, mixing, wet granulation or extrusion granulation, drying and cooling, screening, and packaging. In the production process, it is necessary to select appropriate granulation equipment and processes according to product requirements to ensure the quality and production efficiency of the granules. At the same time, equipment maintenance and quality control are also important links to ensure product quality and production efficiency.

In summary, disc granulators and extrusion granulators are commonly used granulation equipment in the production of bentonite cat litter particles, and they play a vital role in the production process. By selecting suitable granulation equipment and strictly controlling the production process, bentonite cat litter particles with stable quality, uniform particles, and good agglomeration can be produced to meet market demand and enhance competitiveness.