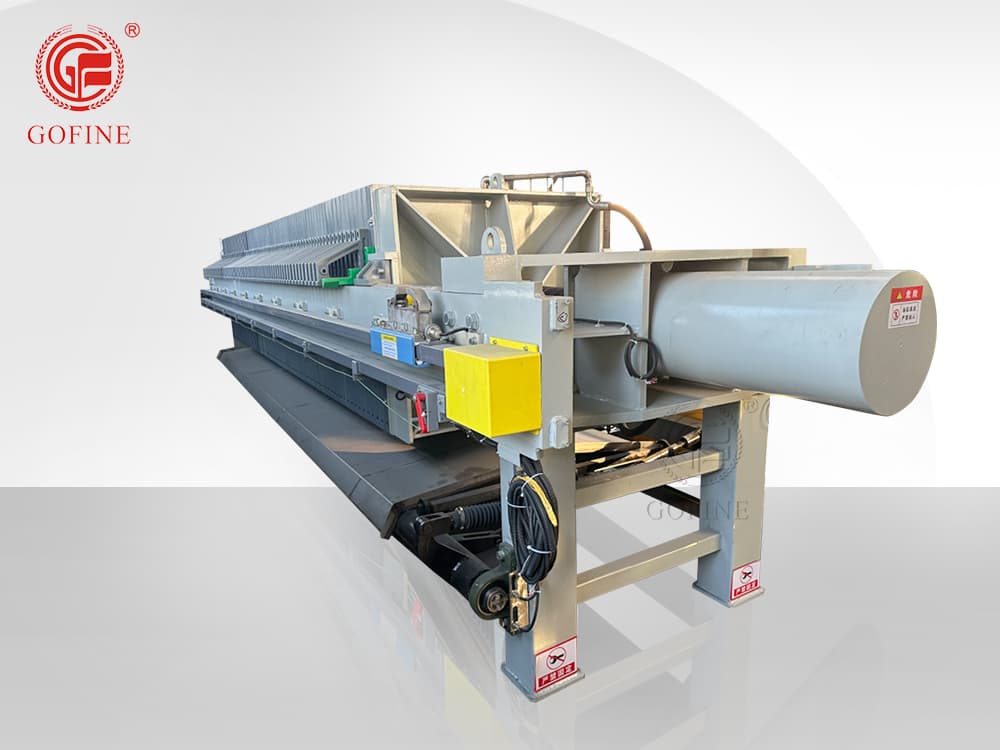

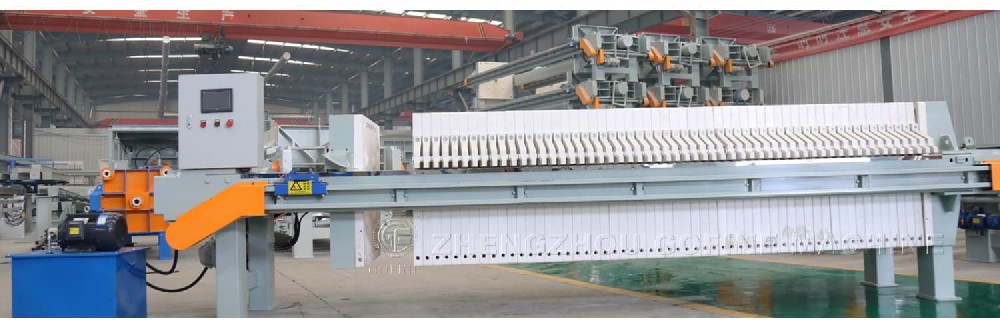

High pressure chamber filter press

- Information

Introduction of Chamber Filter Press

Chamber filter press is a common solid-liquid separation equipment, widely used in the solid-liquid separation process in industrial production.

Chamber filter press is mainly composed of chamber, filter plate, hydraulic system, filter medium and control system.

Among them, the chamber is the main working part, which is composed of multiple filter plates and end plates, and the filter medium is filled between the filter plates and the end plates. The hydraulic system pushes the filter plate to press the filter medium to make the filtering effect better. The control system provides support for the stable operation of the chamber filter press.

Compared with other filter press equipment, the chamber filter press has a large filtration area and strong production capacity. It is especially suitable for filtering materials with more granular objects, such as sewage treatment, mineral processing, coal washing and other industries.

Features of Chamber Filter Press

Automated operation

The chamber-type fully automatic filter press adopts an automated control system, which can realize the automation of the operation process, reduce manual intervention, and reduce labor intensity.

Large processing capacity

The equipment structure is multi-chamber, and through multiple pressing steps, continuous solid-liquid separation is achieved, with a large processing capacity.

Good filtration effect

The chamber-type fully automatic filter press adopts high-quality filter cloth and filter plate, which can effectively filter solid materials, make the filtrate clearer, and the filtration effect is better.

Energy saving

The chamber-type fully automatic filter press fully considers energy consumption during design and operation, and adopts technologies such as rapid filtration and efficient dehydration, which can effectively save energy.

Stable and reliable

The equipment adopts high-quality materials, has a solid structure, good durability, and stable and reliable operation.

Strong flexibility

The chamber-type fully automatic filter press can adjust parameters such as pressing force and filtration time according to the characteristics of the material and processing requirements to adapt to different process requirements.

Multiple application fields

The chamber-type fully automatic filter press is widely used in chemical, metallurgical, pharmaceutical, food processing, environmental protection and other industries, and can be used for filtration, concentration, dehydration and other processes.

Application of Chamber Filter Press

As a solid-liquid separation equipment, chamber filter press has a wide range of application scenarios in various industrial fields, including but not limited to the following aspects:

Chemical industry: Used in solid-liquid separation, dehydration and other processes in chemical production, such as separating solid particles in suspension or filtering organic synthesis reaction products in chemical production.

Food processing industry: Used in slurry separation, juice extraction and other links in food production, such as separating solid residues in juice in juice production.

Mining industry: Used in ore dehydration, tailings treatment and other processes, such as separating solid particles from liquid in metal ore extraction.

Environmental protection engineering: Used to treat suspended matter, sludge, etc. in wastewater, to achieve solid-liquid separation to purify water quality.

Pharmaceutical industry: Used in solid-liquid separation, dehydration and other processes in pharmaceutical production, such as separating solid impurities in liquid medicine in drug production.

Textile industry: Used in slurry separation and other links in textile technology to help achieve solid-liquid separation requirements in textile production.

Technical Parameters of Chamber Filter Press

| Model | Filter area (㎡) | External dimensions (mm) | Filter cake thickness (mm) | Filter chamber volume (L) | Filter plate quantity (pcs) | Motor power (kw) | Dimensions (mm) |

| GF100 | 100 | 1250x1250 | 30 | 1506 | 36 | 5.5 | 8307 517x1850x1600 |

| GF200 | 200 | 1500x1500 | 30 | 3025 | 49 | 11 | 6640x2100x1820 |

| GF400 | 400 | 1500x1500 | 30 | 6049 | 99 | 11 | 10140x2100x1820 |

| GF600 | 600 | 2000x2000 | 40 | 12000 | 83 | 11 | 10890x2100x1820 |

Working Process of Chamber Filter Press

When the chamber filter press is filtering, the slurry enters the chamber from the feed port. Under the action of pressure, the liquid in the slurry passes through the filter medium and is discharged from the filtrate port, while the solids are left inside the chamber. As the filtering operation proceeds, the solids gradually accumulate at the bottom of the chamber to form a filter cake. When the filter cake accumulates to a certain thickness, it can be unloaded from the chamber, completing the entire filtering process.

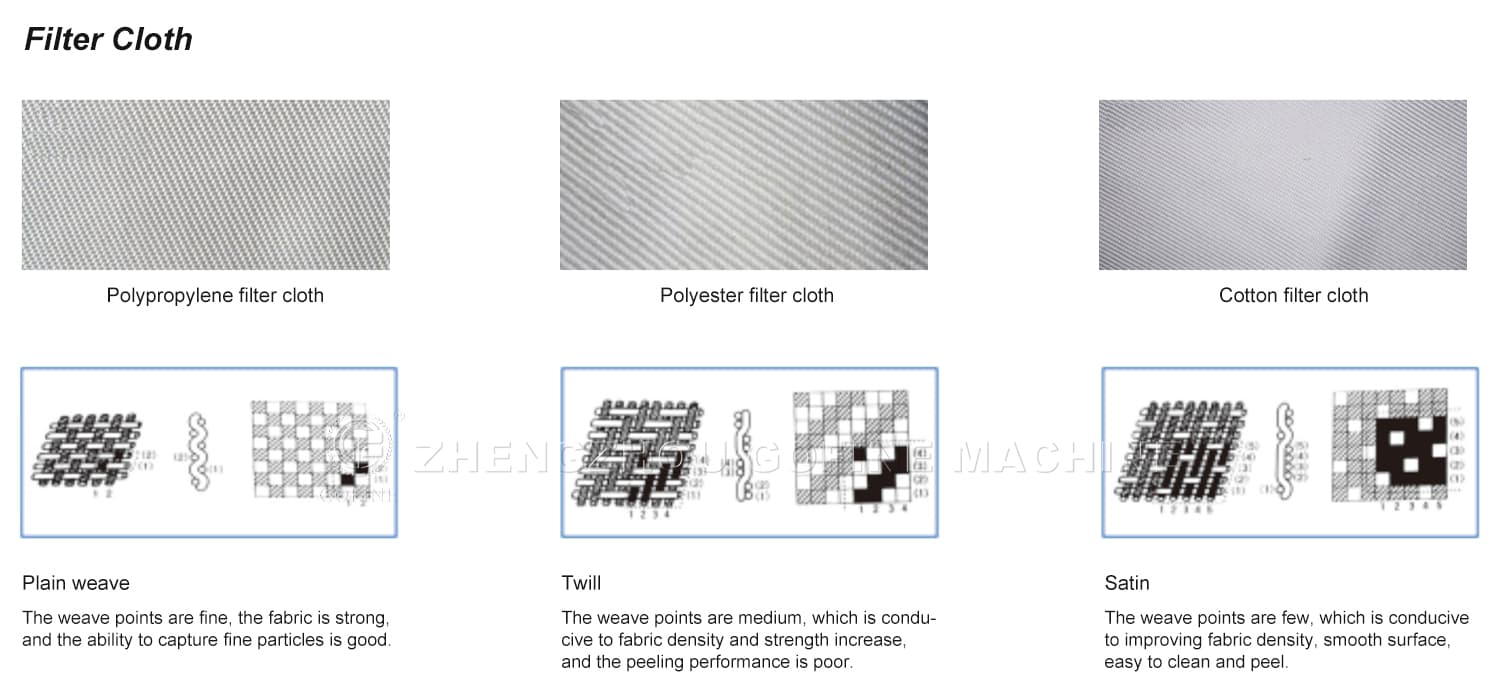

Related Accessories of Chamber Filter Press

Introduction to the main performance of chamber filter press filter cloth

| Properties | Terylene | Nylon | Polypropylene | Vinylon |

Acid resistance | Good | Poor | Good | Poor |

Alkali resistance | Weak alkali resistance | Good | Good | Good |

Breaking strength (g/d) | 4.3-9 | 4.5-9.5 | 4.5-9 | 4-10 |

Breaking elongation (%) | 20-50 | 20-40 | 18-35 | 12-26 |

| Softening point (℃) | 238-240 | 180-235 | 140-160 | 220-230 |

Melting point (℃) | 255-260 | 215-260 | 165-173 | Not obvious |

| Specific gravity | 1.38 | 1.14 | 0.91 | 1.26-1.30 |

| Chemical name | Polyethylene terephthalate | Polyamide | Polypropylene | Polypropylene |

Chamber Filter Press Filter Plates

The filter press filter plates produced by our company include: enhanced polypropylene filter plates, glass fiber polypropylene filter plates, rubber diaphragm filter plates, cast iron filter plates, stainless steel filter plates, etc.

According to the feeding method, it can be divided into: middle feeding, corner feeding, upper middle feeding, etc.

Users can choose the appropriate filter plate material according to the different production process requirements of their own products.

If you want to know more about our products, please contact us! I will serve you wholeheartedly!