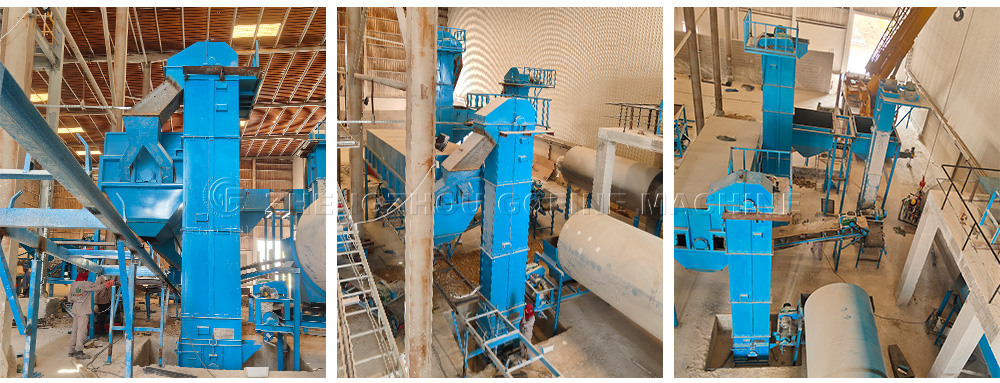

Bucket Elevator

- Information

Introduction of Bucket Elevator

A bucket elevator is a piece of equipment specially designed to transport materials, suitable for various powdery, granular, and block materials.

The method of vertically lifting materials is used to continuously or intermittently lift materials from low to high to a designated position.

The transmission speed can be adjusted according to the transmission volume, and the lifting height can be adjusted according to needs.

Bucket elevators have the advantages of high efficiency, stability, and strong processing capabilities. They are widely used in many industries, improving production efficiency and reducing labor costs. It also has the characteristics of environmental protection, energy saving, and safety.

Feature of Bucket Elevator

1. Vertical transportation: Effectively overcomes height restrictions and can lift materials from low to high or transport materials from high to low.

2. Small footprint: Compared with other transportation equipment, the bucket elevator occupies a smaller area and can achieve efficient material transportation within the space.

3. High conveying efficiency: The bucket elevator has a large capacity and can convey more materials at one time, improving conveying efficiency and production capacity.

4. Strong adaptability: It can handle materials with different humidity and particle size to meet a variety of needs.

5. Reliable and stable: The hoist runs smoothly during transportation and is equipped with safety protection systems, such as overload protection and emergency shutdown devices.

6. Low maintenance cost: The equipment has a simple structure, easy for later maintenance and maintenance, and has a long service life.

Working Process of Bucket Elevator

The bucket elevator uses a vertical or inclined conveying method to transport materials from one end to a designated location.

The materials are first thrown into the elevator hopper from the silo or pile. After the bucket elevator is started, the motor drives the chain or wheel and other transmission devices to make the elevator rise along the column or track. When the material reaches the discharge point, the elevator hopper turns over and the material falls into the designated target position. After the materials have been transported, the elevator descends to the starting position to transport the next set of materials and cycle the operation.

Bucket elevators can be equipped with automatic weighing and detection devices to achieve quantitative transportation and real-time monitoring.

Technical Parameter of Bucket Elevator

| Type | 20/11 | 26/13 | 36/18 | 50/28 |

| Lifting capacity (m) | 3-7 | 4-10 | 5-18 | 11-30 |

| Line speed (m/s) | 57 | 59 | 42 | 40 |

| Spindle diameter (mm) | 200 | 260 | 360 | 500 |

| Rotate speed (r/min) | 115 | 90 | 80 | 65 |

| Power (kw) | 0.55-1.5 | 0.75-1.5 | 1.1-2.2 | 1.5-5.5 |

Product Details of Bucket Elevator