High-Efficiency Fabric Filter Baghouse Dust Collector for Industrial Use

- Information

A baghouse dust collector (also known as a bag filter, fabric filter, or baghouse filter) is an air pollution control device used to remove particulate matter from industrial exhaust streams. It's one of the most common and efficient types of dust collection systems used in a variety of industries.

Features

High Efficiency: Can capture a wide range of particle sizes, including coarse and fine dust, with collection efficiencies greater than 99%.

Versatility: Suitable for various industries and applications with different dust types and loads.

Durability: Robust construction for heavy dust loads and demanding environments.

Effective for High Dust Loads: Especially effective for industries handling high dust loads, coarse particles, or sticky dust.

Environmentally Friendly: Reduces airborne contaminants, promoting cleaner air and helping industries meet strict environmental and safety standards.

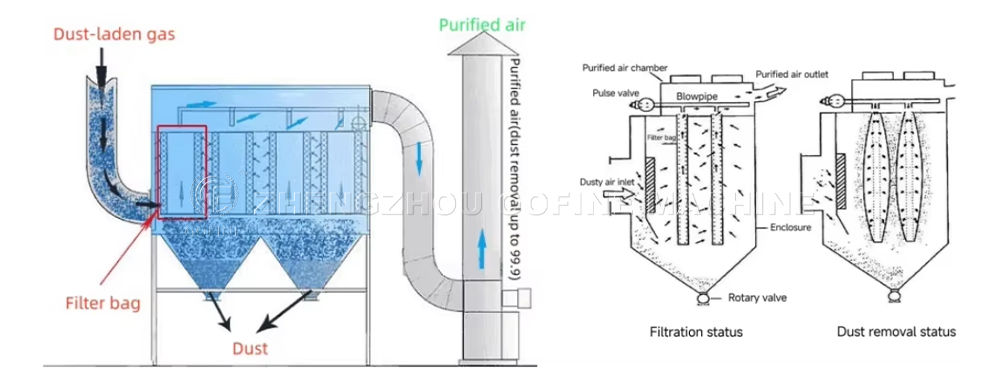

Working Principle

Bag dust collector uses advanced filter bags to filter dusty air, and has functions such as waterproof, oil-proof and easy to clean. It is sprayed regularly through a pulse solenoid valve to knock down the dust and collect it.

Core components:

1. Cylinder

Bag filter consists of three parts: upper cylinder, middle cylinder and lower cylinder.

The upper cylinder is used as a channel for clean air after filtration, and the middle cylinder is an important part for dust removal, which is used to install the frame and filter bag.

The lower cylinder plays a role in collecting dust after being knocked down.

2. Filter bag

The compressed air quickly enters the filter bag through a special pipe for spraying. These filter bags are supported by the frame to prevent the filter area from being reduced after empty suction, and to achieve a more efficient filtering effect.

3. Blowing pipe, solenoid valve

The compressed air is sprayed regularly through the solenoid valve, and the airflow is induced through the venturi tube to enhance the dust cleaning effect.

4. Pulse controller

It controls the timing switch of the solenoid valve, thereby controlling the frequency and duration of compressed air spraying, so as to achieve precise control of the cleaning cycle of the bag filter.

Technical Parameters

| Model | GF-32 | GF-36 | GF60 | GF-120 | GF-160 | GF-320 |

| Filter bag specifications (mm) | Φ 120x1000 | Φ125x1000 | Φ 120x2000 | Φ 120x2000 | Φ 120x2000 | Φ 120x2000 |

| Filter area | 12㎡ | 14㎡ | 45㎡ | 90㎡ | 120㎡ | 240㎡ |

| Matching fan | 3kw | 3kw | 15kw | 30kw | 55kw | 132kw |

| Fan air volume | 1558m³/h | 1558m³/h | 4000-4900m³/h | 5690-6978m³/h | 12700-13500m³/h | 21800m³/h |

| Wind pressure | 3380 Pa | 3380 Pa | 6400-6950 Pa | 8178-8857 Pa | 8300-8630 Pa | 11800 Pa |

| Injection pressure | (0.6-0.7) Mpa | |||||

| Filter bag material | Oil waterproof needled felt | |||||

| Applications | Fertilizer Production Line, Cement Manufacturing, Power Plants, Steel Mills, Pharmaceuticals, Food Processing, Woodworking, Chemical Processing, Mining, Asphalt Plants, Agriculture, etc. | |||||

Common Issues:

Clogged Bags: Caused by sticky dust or moisture.

Air Leaks: Can reduce efficiency and release dust.

Improper Cleaning: Results in higher pressure drops and reduced airflow.

Daily maintenance

Clogged Bags: Control humidity, adjust cleaning, use proper filter, and consider pre-coating. Regularly inspect, clean, and replace bags as needed.

Air Leaks: Check/repair seals, welds, and connections. Use leak detection methods and maintain a regular inspection schedule.

Improper Cleaning: Adjust cleaning parameters (frequency, pressure), inspect pulse valves & nozzles, ensure clean compressed air. Calibrate the cleaning system.

Baghouse dust collectors are a reliable and efficient solution for controlling air pollution in industrial settings by removing particulate matter from exhaust streams.

If you have related equipment needs or solution designs, please feel free to contact me!

Product Details