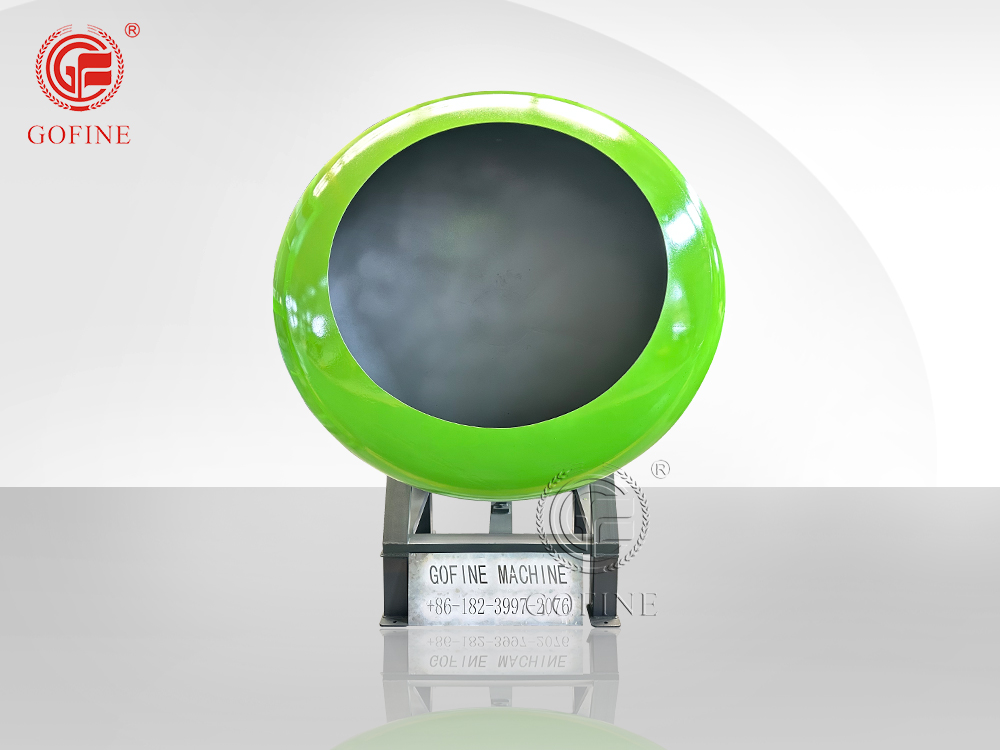

Pot type fertilizer granulator organic fertilizer granule making machine

- Information

Introduction of organic fertilizer granule making machine

The round pot organic fertilizer pellet processing machine is a highly efficient granulation equipment, which is mainly used to process organic fertilizer raw materials into spherical granular fertilizer. The working principle of the equipment is to use the inclined disc to continuously roll the wet powdered material under the action of centrifugal force and friction, gradually forming particles, and the ball formation rate is as high as 95% or more. It has the characteristics of simple operation and strong adaptability.

Features of organic fertilizer granule making machine

1. High pelletization rate:

The granulator adopts a unique round pot design, which makes the pelletization rate of fertilizer granules as high as 95%, with high production capacity.

2. Sturdy and durable:

The granulator material can be selected from carbon steel or stainless steel, which is sturdy and durable, and also has corrosion resistance.

3. Easy to maintain:

The machine has a simple structure and the lining is easy to clean, which reduces maintenance costs.

4. Strong adaptability:

The round pot granulator is suitable for the processing of a variety of raw materials, especially for processing materials with low viscosity, and can meet different production needs.

Working principle of organic fertilizer granule making machine

The working principle of the round pot granulator is mainly to convert powdered materials into granular fertilizers through mechanical movement. First, the powdered materials are evenly added to the round pot through the feed port, and an appropriate amount of water is sprayed in the pot to wet the powder. Then, the round pot starts to rotate driven by the transmission device, and the axis of the pot is at a specific angle to the horizontal plane. The wet powder rolls in the pot and gradually forms a ball core with the help of centrifugal force and friction. As the material continues to roll, rub and collide, the ball core gradually grows and forms particles. When the particles reach the required particle size, they are discharged through the discharge gate. The whole process is efficient and stable, suitable for large-scale fertilizer production needs.

Product parameters of organic fertilizergranule making machine

| Volume | Production capacity | Speed | Power |

| 2-20 m³ | 1-15t/h | 24-14 r/m | 55 kw |

| The material can be carbon steel or stainless steel. A variety of models are available to meet different production needs and support customization. | |||

Services we provide:

1. Professional technical consultation to help you choose the most suitable fertilizer equipment.

2. Equipment installation and commissioning to ensure the normal operation of the equipment.

3. We provide detailed operation training to ensure that personnel can master the equipment proficiently.

4. Provide long-term after-sales support to ensure that the equipment remains in good condition during use.

Detail pictures of organic fertilizer granule making machine