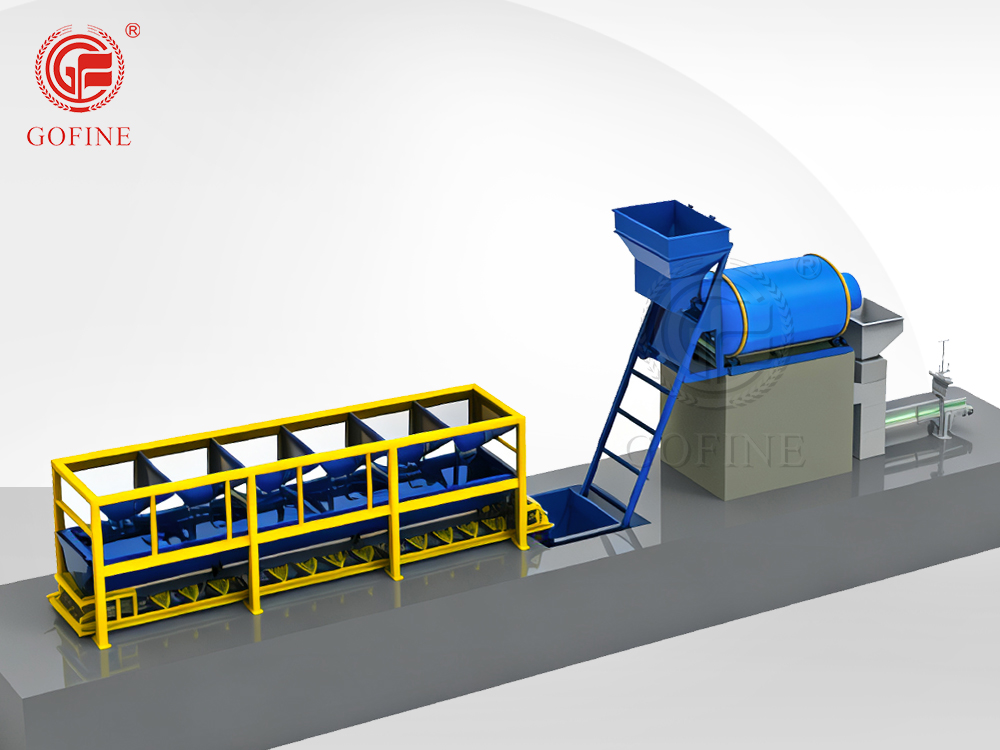

Bulk Blending Plant BB Fertilizer Production Line Manufacturer

- Information

Overview

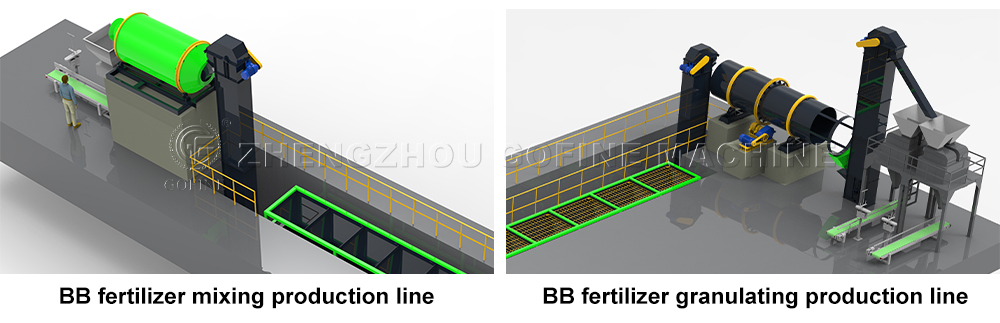

BB fertilizer, also known as bulk blended fertilizer, is a high-efficiency compound fertilizer produced by blending multiple single-nutrient or multi-nutrient compound fertilizer granules in precise proportions according to soil conditions, crop needs and fertilization purposes. The Gofine BB Fertilizer Production Line is a professional integrated production system designed for the efficient manufacturing of high-quality BB fertilizer. It integrates raw material batching, high-speed mixing, granulation, coating, screening and packaging processes, enabling flexible production of customized BB fertilizer products. This production line is capable of mixing various compound fertilizer granules, achieving uniform nutrient distribution through advanced mixing tanks, and producing professional BB fertilizer granules with stable quality via drum granulators and coating equipment, fully meeting the demands of modern precision agriculture.

Features

- Precise Batching & Uniform Nutrients: Equipped with high-precision automatic batching machines and electronic weighing systems, the production line ensures accurate proportioning of nitrogen, phosphorus, potassium, micronutrients and other raw materials, with a batching error controlled within 0.5%. The specialized mixing tank adopts spiral mixing technology, realizing fast and uniform mixing of various compound fertilizer granules, eliminating nutrient segregation and ensuring consistent nutrient content in each BB fertilizer granule.

- Flexible Granulation & Coating: Optional drum granulator enables the production of spherical BB fertilizer granules with moderate hardness, which are not easy to agglomerate during storage and transportation. The matching coating machine can spray anti-caking agents, slow-release agents or functional coating materials, improving the anti-caking performance, storage stability and nutrient release efficiency of the final product, and expanding the product range to meet diverse market demands.

- Efficient & Energy-Saving Operation: The whole line adopts PLC intelligent control system, realizing automated operation from raw material feeding to finished product packaging, greatly reducing labor costs and production cycle. The enclosed structure and professional dust removal equipment effectively control dust emissions, complying with environmental protection standards, while optimizing energy consumption design to lower operational costs.

- Strong Adaptability: It can flexibly mix various compound fertilizer granules, including urea-based compound fertilizer, NPK compound fertilizer, organic-inorganic compound fertilizer, etc. The production parameters can be easily adjusted to switch between different formulas, supporting the production of crop-specific, soil-specific and seasonal BB fertilizers.

- Stable Product Quality: Through standardized production processes and multi-stage screening systems, unqualified granules are separated and recycled, ensuring the finished BB fertilizer has uniform particle size, stable nutrient content and excellent application effect.

Applications

The Gofine BB Fertilizer Production Line is widely applicable to agricultural production bases, fertilizer manufacturing enterprises, and agricultural cooperatives, suitable for producing BB fertilizers for various crops and soil types, including:

- Field Crops: Rice, wheat, corn, cotton, soybeans, etc., providing balanced nutrients to promote high yield and quality.

- Horticultural Crops: Vegetables, fruits, flowers, etc., supporting customized nutrient formulas to meet the growth needs of different horticultural crops at various stages.

- Cash Crops: Tobacco, tea, medicinal herbs, etc., realizing precise fertilization to improve the special quality of cash crops.

- Green Agriculture: Compatible with organic raw materials and slow-release additives, it can produce green, environmentally friendly and efficient BB fertilizers, adapting to the development trend of sustainable agriculture.

Production Process Flow

1. Raw Material Pretreatment: Raw materials such as compound fertilizer granules, single-nutrient fertilizers and micronutrients are crushed (if needed) and screened to remove impurities and agglomerates, ensuring uniform particle size for subsequent processes.

2. Automatic Batching: According to the preset formula, the batching machine automatically weighs and conveys various raw materials to the mixing tank through a conveying system, realizing precise proportioning.

3. High-Speed Uniform Mixing: The mixing tank operates with spiral blades for forward and reverse rotation, fully mixing the raw materials in a short time to ensure uniform nutrient distribution without segregation.

4. Granulation (Optional): The mixed materials are sent to the drum granulator, and under the action of rotation and appropriate binding agents, spherical BB fertilizer granules are formed.

5. Drying & Cooling: The newly formed wet granules are dried in a dryer to reduce moisture content (controlled below 10%) and then cooled to room temperature by a cooler to improve granule strength and stability.

6. Coating (Optional): The dried and cooled granules enter the coating machine, where anti-caking agents, slow-release agents or other functional materials are sprayed to form a protective film on the surface.

7. Grading & Screening: The finished granules are screened by a vibrating screen to separate qualified granules, oversize granules and fine powders. Oversize granules are crushed and recycled, while fine powders are returned to the mixing process for reprocessing.

8. Automatic Packaging: Qualified BB fertilizer granules are quantitatively packaged into 25kg, 50kg or other specifications by an automatic packaging scale, and then sealed and conveyed to the finished product warehouse for storage.

Why choose Gofine BB Fertilizer Production Lines?

- Professional Technology, Reliable Quality: Gofine has extensive experience in fertilizer equipment research and manufacturing. Our BB fertilizer production lines utilize mature core technologies such as precise proportioning, efficient mixing, and stable granulation. Key components are sourced from renowned brands, ensuring long-term stable operation and reliable product quality.

- Customized Solutions: We provide tailored production line designs based on customer production capacity (1 ton/hour to 30 tons/hour), product requirements (ordinary BB fertilizer, slow-release BB fertilizer, etc.), and investment budget, maximizing the satisfaction of our customers' individual needs.

- Economical and Efficient Operation: Compared to traditional production methods, our automated design reduces labor costs by more than 30%. Energy-saving structures and material recycling systems minimize energy consumption and raw material waste, significantly reducing overall operating costs.

- Comprehensive Function Integration: The production line integrates mixing, granulation, coating, and packaging, eliminating the hassle of separate equipment procurement and assembly. This ensures seamless connection between each process step and improves production efficiency.

- Compliance with Environmental Standards: The production line is equipped with a complete set of dust removal, exhaust gas treatment, and noise reduction equipment, complying with national and international environmental protection requirements and helping customers achieve green production.

As a comprehensive fertilizer equipment supplier, GOFINE offers more than just BB fertilizer production lines. We provide a complete portfolio of fertilizer manufacturing solutions, including NPK compound fertilizer production lines, organic fertilizer production lines, urea granulation lines, and slow-release fertilizer production lines. All lines share the same high-quality components, intelligent control technology and strict quality standards, enabling customers to expand their product portfolio and build a one-stop production system in line with their business development plans.