Roller extruder granulator: ideal for efficient fertilizer production

2025-01-25In modern agriculture, high-quality fertilizers are the key to improving crop yield and quality. Choosing the right granulator production equipment is crucial for fertilizer manufacturers. As a professional fertilizer equipment manufacturer, our roller extruder granulator has become an ideal choice for fertilizer production due to its excellent performance and multiple advantages.

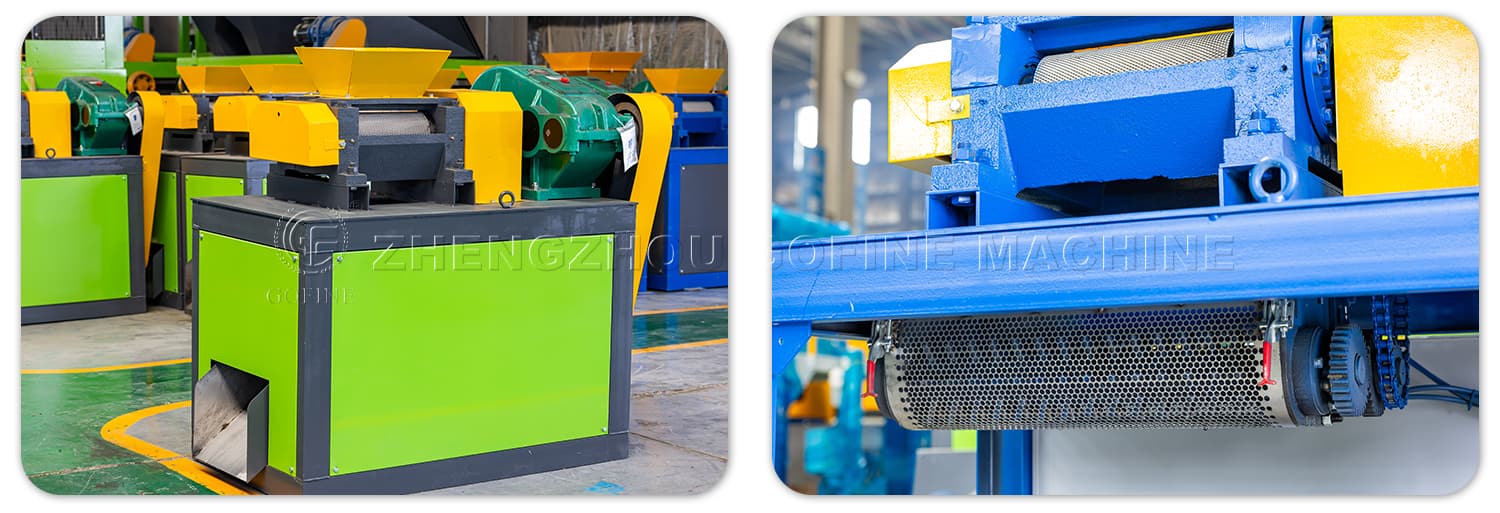

What is a double roller extrusion granulator?

A double roller extrusion granulator is a device that compresses materials into granules by applying pressure between two rollers. This device is widely used in many industries such as fertilizers, chemicals, and food, and is especially suitable for the processing of dry powder materials.

Advantages of the double roller extrusion granulator

1. Efficient production capacity

The double roller extrusion granulator can quickly press raw materials into granules, significantly improve production efficiency, and meet the needs of large-scale fertilizer production.

2. Reduce energy consumption

Compared with traditional wet granulation, the double roller extrusion granulator reduces the use of water and the subsequent drying process, thereby reducing energy consumption and helping companies save operating costs.

3. Stable granule quality

The granules produced by this equipment have high density and uniform shape, which can improve the solubility and nutrient release rate of fertilizers and ensure that crops obtain balanced nutrition.

4. Easy to operate

The design of the double roller extrusion granulator focuses on user experience, simple operation, convenient maintenance, and reduces labor costs and equipment downtime.

Customer Pain Points and Solutions

1. Low Production Efficiency

Many fertilizer manufacturers face the problem of low production efficiency, which leads to the inability to meet market demand. Our double-roll extrusion granulator helps companies improve production efficiency with its efficient production capacity.

2. High energy consumption

The energy consumption of the equipment directly affects the company's profits. The double-roll extrusion granulator significantly reduces energy consumption through optimized design, saving operating costs for the company.

3. Unstable product quality

Fluctuations in product quality can affect the growth of crops. Our equipment ensures the consistency and stability of the particles and improves the overall quality of the fertilizer.

4. High maintenance cost

The maintenance and care of the equipment often consumes a lot of time and resources. The double-roll extrusion granulator uses wear-resistant materials to extend its service life and reduce maintenance frequency and costs.

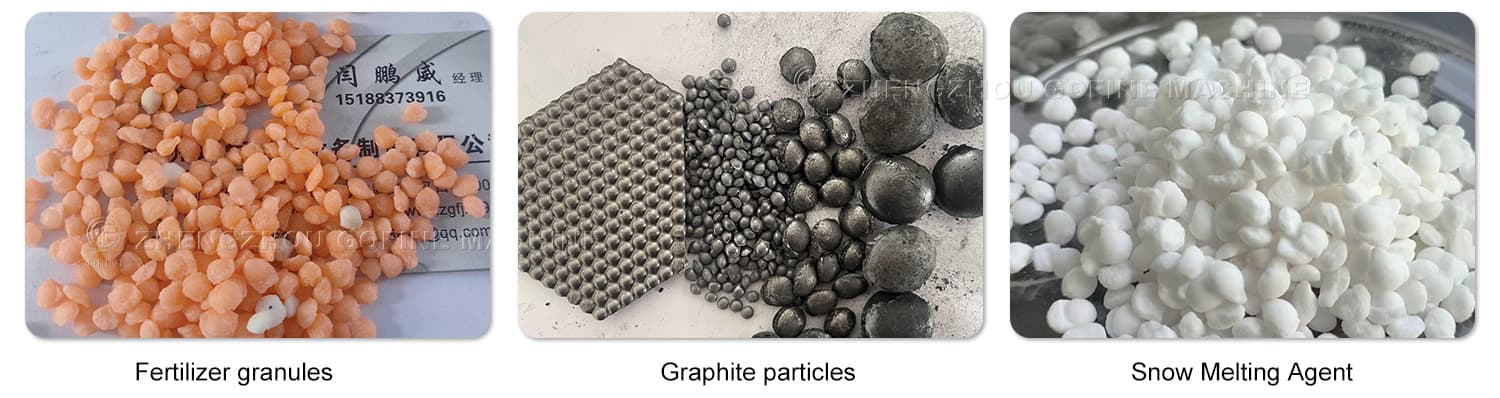

Application of double roller extrusion granulator

Due to its high efficiency and flexibility, double roller extrusion granulator is widely used in various granule processing, mainly including the following categories:

Pig manure straw organic fertilizer granulation

NPK granulation

De-icing agent granule production

Graphite granulation

Gypsum and limestone granulation

Conclusion

The double roller extrusion granulator is an indispensable and important equipment in the fertilizer production process, which can effectively solve the various pain points encountered by customers in production. As a professional fertilizer equipment manufacturer, we are committed to providing high-performance equipment and high-quality services to help customers succeed in the fierce market competition.

We have more granulation equipment for you to choose from, welcome to contact us! We will provide you with professional solutions to help you stand out in the fertilizer industry.