Organic Fertilizer Production Line Project | Complete Guide for Fertilizer Plant Setup

2025-08-11With the rising demand for eco-friendly agriculture, more investors and farmers are turning to organic fertilizer production lines as a profitable and sustainable business. Organic fertilizers not only improve soil fertility but also help recycle agricultural and livestock waste.

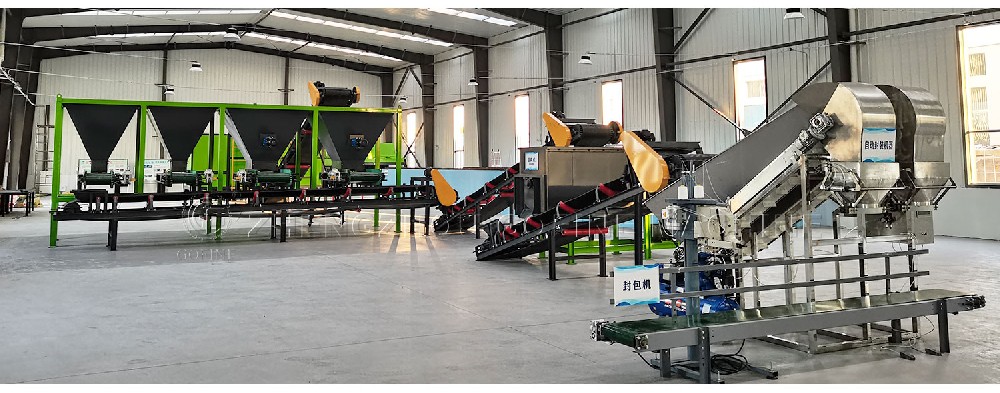

Gofine Machine provide complete solutions for starting an organic fertilizer plant, including organic fertilizer equipment, project planning, machine supply, installation, and after-sales support.

Step-by-Step Guide: How to Start an Organic Fertilizer Production Line Project

1. Analyze the Raw Materials

The first step is to determine what organic materials you will use. Common raw materials include:

Cow dung, pig manure, chicken manure

Crop residues, straw, sugarcane bagasse

Food waste, sludge, biogas residues

Compost additives (peat, zeolite, bacteria)

Understanding your raw materials helps in choosing the right organic fertilizer equipment and process.

2. Choose the Right Production Scale

Based on expected output, you can select:

Small-scale fertilizer plant: 1–3 tons/hour

Medium-scale fertilizer line: 5–10 tons/hour

Large-scale fertilizer factory: 20+ tons/hour

We offer customized fertilizer plant solutions based on your capacity and budget.

3. Select the Necessary Organic Fertilizer Equipment

Here is a typical organic fertilizer production line layout:

| Equipment | Function |

| Dewatering Machine | Reduces moisture of animal waste to <60% |

Compost Turner | Accelerates fermentation of organic materials |

| Crusher | Breaks down compost lumps into fine powder |

| Mixer | Blends compost with nutrients or additives |

Fertilizer Granulator | Shapes powder into uniform granule |

Dryer & Cooler | Reduces the moisture and temperature of granules |

| Screener | Classifies granules by size |

Packing Machine | Automatically bags the final product |

4. Design the Layout of Your Fertilizer Plant

A well-designed fertilizer plant layout improves workflow and reduces operational costs. We provide:

3D design and process flow chart

Factory layout planning

Power and water source distribution

Installation & commissioning guidance

5. Consider Environmental Compliance

Modern organic fertilizer making machines are equipped with:

Dust collectors

Wastewater filtration systems

Noise reduction mechanisms

These help your plant comply with local environmental regulations and ensure sustainable production.

6. Granulation: The Core of Fertilizer Production

The fertilizer granulator is the heart of the line. We offer:

Disc granulators – Ideal for small-scale and low-cost production

Rotary drum granulators – Durable and suitable for mass production

New type organic fertilizer granulators – Suitable for pure organic materials

Flat die granulators – For organic fertilizer pellets without drying

Choosing the right granulator machine determines your product shape, strength, and market value.

7. Packaging and Storage

The last step is automatic packing using a fertilizer packing machine. Options include:

25kg–50kg bag filling

Bulk bagging systems

Weighing and sealing integration

Proper packaging ensures product quality and shelf life.

Why Invest in an Organic Fertilizer Production Line?

✅ Turn agricultural waste into profit

✅ Reduce environmental pollution

✅ Meet growing demand for organic farming inputs

✅ Government subsidies in many countries

✅ High return on investment within 1–2 years

If you're planning to launch an organic fertilizer manufacturing project, we’re here to guide you from concept to completion. Contact us today for a customized solution, machine list, factory layout, and project quotation.