Low cost construction of a phosphate fertilizer granulation production plant

2024-12-31As an essential nutrient in agricultural production, phosphate fertilizer plays an important role in increasing crop yields and improving soil fertility.

Building a phosphate fertilizer production plant can help you obtain high-quality phosphate fertilizer granules more efficiently. At the same time, it can effectively reduce production costs, ensure the uniformity of fertilizer granules, adapt to market demand, and achieve environmentally friendly and sustainable development.

What preparations are needed to build a complete phosphate fertilizer production line?

Investing in a phosphate fertilizer production plant is a very promising project, but building this fertilizer production line is not an easy task.

You need a detailed business plan for the fertilizer production plant, and make good plans from multiple aspects such as raw material selection, site, fertilizer equipment, production requirements and sales channels. I have sorted out some of the work that needs to be done to build a phosphate fertilizer production plant:

1. Project planning and design

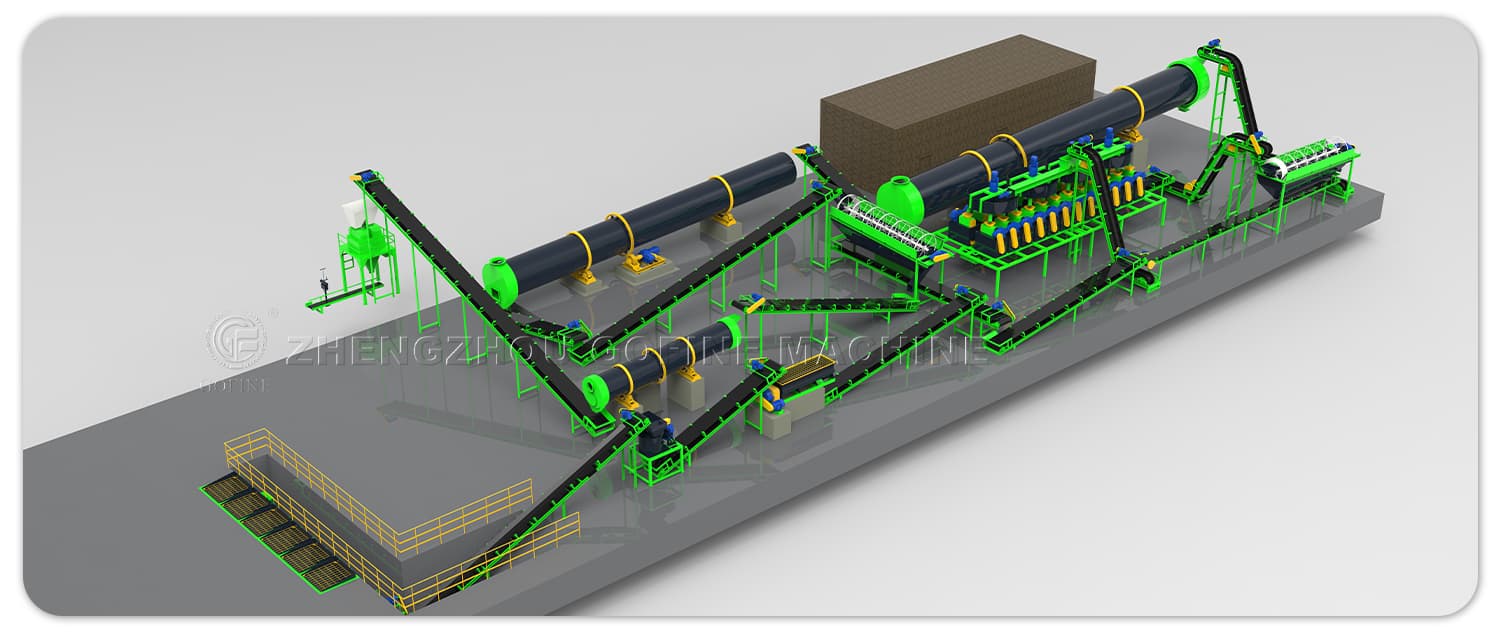

Determine the scale, production capacity and technical requirements of the phosphate fertilizer production line, and formulate a detailed project planning and design plan, including process flow, equipment selection, etc.

2. Site selection and preparation

Select a site suitable for the construction of a phosphate fertilizer production line, consider convenient transportation, environmental factors and the possibility of future expansion, and carry out site preparation and leveling work.

3. Apply for relevant licenses and procedures

Apply for various licenses and procedures required for the construction project, including environmental protection approval, construction project planning license and other relevant documents.

4. Purchase equipment and raw materials

According to the design plan and production needs, purchase various equipment, machinery and raw materials required for the production line to ensure equipment quality and production stability.

5. Construction project construction

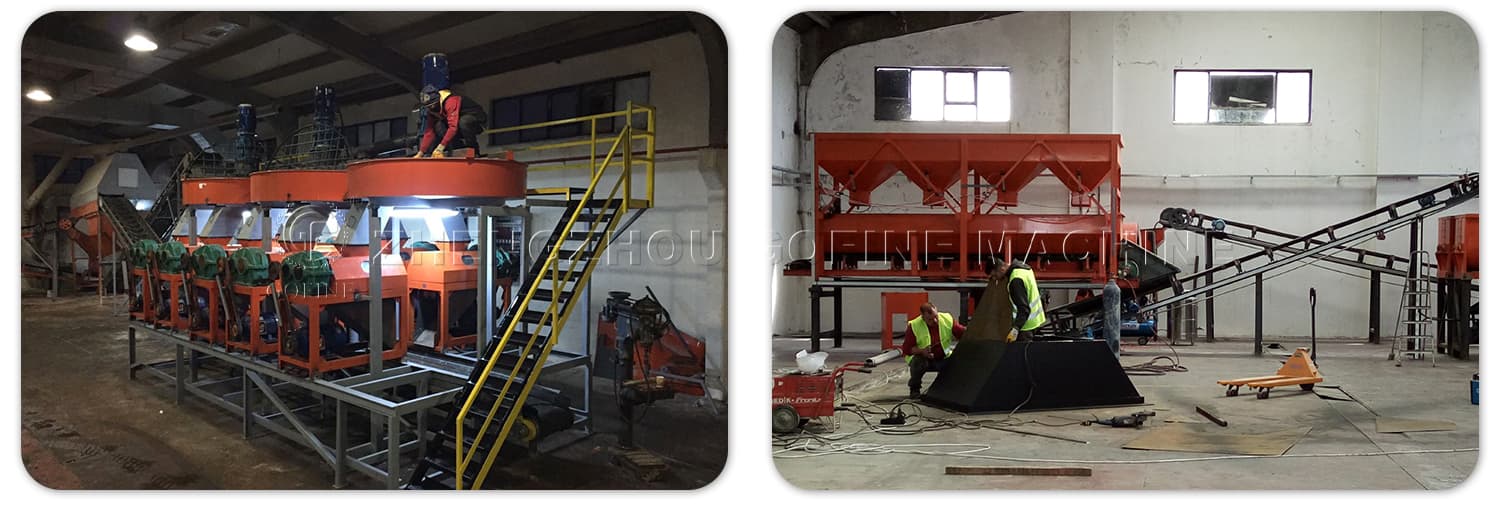

Carry out civil engineering and equipment installation work, including plant construction, pipeline installation, equipment commissioning, etc., to ensure the smooth construction of the production line.

6. Power and energy supply

Ensure that the production line has a stable power supply and other energy supply, consider energy-saving and environmental protection solutions, improve production efficiency and reduce energy consumption.

7. Human resource preparation

Recruit and train technicians and operators required for the production line to ensure sufficient and professional human resources.

8. Safety production measures

Formulate safety production rules and regulations, equip necessary safety facilities and safety equipment to ensure safe and stable production process.

9. Environmental protection measures

For pollutants such as wastewater and waste gas generated during the production of phosphate fertilizers, formulate corresponding treatment and discharge measures to meet environmental protection requirements.

10. Quality control system

Establish a complete quality control system to monitor the key links in the production process and ensure that product quality meets the standards.

As we all know, a detailed business plan for a fertilizer production plant helps to ensure the smooth implementation and successful operation of a fertilizer production project.

Now you must have a general direction for your phosphate fertilizer production plant. The next key step is how to choose phosphate fertilizer production equipment. This will make your fertilizer production project more efficient.

Gofine sells Frtilizer Fermentation Equipment, Granulators, Mixers, Crushers, Rotary dryers, Coolers, Packaging Machines, Belt Conveyors and other Auxiliary Equipment.

Help you achieve automation and large-scale production.

We provide high-quality fertilizer production equipment, free customization of the best solutions and technical support.

24-hour online, remote training or on-site installation services. Provide you with one-stop procurement services!

You need to determine the raw materials of the fertilizer plant, which determines the production process of the fertilizer equipment.

In fertilizer production, the commonly used phosphate fertilizers mainly include the following:

Single element phosphate fertilizer: including potassium dihydrogen phosphate (MKP for short), ammonium dihydrogen phosphate (MAP for short), etc.

Compound phosphate fertilizer: including mixed phosphate fertilizers containing different elements, such as nitrogen-containing compound phosphate fertilizers, potassium-containing compound phosphate fertilizers, etc.

Phosphate rock phosphate fertilizer: such as apatite, phosphate rock powder, etc., usually need to be treated by phosphorylation before they can be directly used.

Superphosphate: It is a phosphate fertilizer, often used as base fertilizer or topdressing.

Common phosphate fertilizer production plants

Wet phosphate fertilizer production line

Dry phosphate fertilizer production plant

Compound fertilizer phosphate fertilizer production line equipment

Water-soluble fertilizer granulator phosphate fertilizer production line

Slow-release fertilizer granules phosphate fertilizer production line

Each phosphate fertilizer production line has its specific process flow, equipment requirements and product characteristics. According to different raw materials, market demand and production scale, you can choose the appropriate phosphate fertilizer production line for production to meet market demand and improve production efficiency.

Phosphate fertilizer production lines usually require the following types of equipment

Crusher: used to crush raw materials into the required particle size for subsequent process production.

Multi-bin batching machine: used to weigh and mix different raw materials according to a certain ratio, often used in compound fertilizer production lines to ensure the accurate ratio of raw materials in production.

Mixing equipment: used to mix raw materials such as phosphoric acid, urea, potash fertilizer, etc. to ensure uniform fertilizer composition, such as mixers and blenders.

Granulating equipment: used to granulate the mixed fertilizer raw materials, divided into two processes: dry granulation and wet granulation.

Rotary drying equipment: used to dry wet granular fertilizer, such as rotary dryer and bag dryer.

Cooling equipment: used to cool the dried fertilizer particles to prevent agglomeration, such as coolers and air coolers.

Screening equipment: used to screen fertilizer particles of different particle sizes to ensure uniform product particle size, such as vibrating screens and rotary screens.

Packaging equipment: used to package and encapsulate finished fertilizers, such as packaging machines and sealing machines.

Conveying equipment: used for conveying raw materials and finished products, such as belt conveyors and bucket elevators.

Dust removal equipment and waste gas treatment equipment: used to treat dust and waste gas generated during the production process to ensure that the production environment is clean and meets environmental protection requirements.

These equipments play a key role in the phosphate fertilizer production line, ensuring the smooth production process and producing phosphate fertilizer products that meet quality standards. Depending on the production scale and process requirements, the specific equipment combination and configuration may vary.

As a professional fertilizer equipment manufacturer, we always put product quality and customer service first. We strictly implement the ISO quality management system to ensure that each phosphate fertilizer granulation production line meets international standards.

We have more production lines for you to choose from:

If you want to know more about fertilizer equipment, you are welcome to contact me at any time!