Industrial Commercial Composting Equipment Revolutionizing Fertilizer Production

2024-03-06Commercial composting equipment uses advanced industrial composter technology to convert organic waste into high-quality organic fertilizer through scientific fermentation processes to provide crop nutrients and promote soil health and ecological balance.

Our range of industrial composting machinery processes organic waste efficiently and conveniently.

We are also committed to producing various composting solutions to reduce on-site waste in commercial applications.

Advantages of commercial composting compared to traditional waste management methods:

• Compost waste can be converted into organic fertilizer in seven days

• Reduce pollution and odor

• High-temperature sterilization

• Environmentally friendly and sustainable

Commercial Composting Equipment

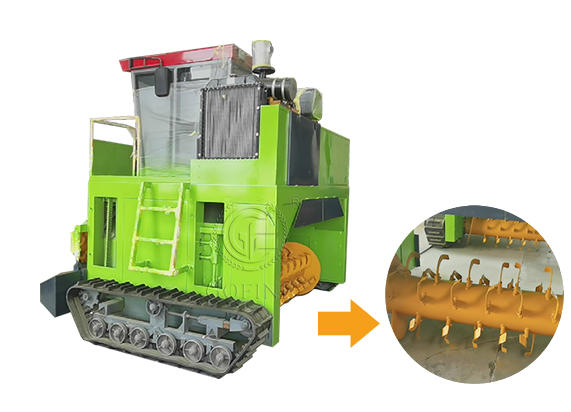

Crawler Type Compost Turner

• 360° flexible flipping

• Easy to drive

• Recycle

Working process of crawler turner

The crawler turner realizes the turning and mixing of organic waste through the turning device. This commercial composter has a cab, so you can drive the composting equipment freely between compost piles or piles. The unique paddle design evenly mixes and throws organic waste, promotes the decomposition and maturity of organic waste, and achieves effective processing and transformation during the composting process.

Tractor-pulled compost turners

As a tractor or semi-trailer type of equipment, it is usually pulled by a powerful tractor.

• Foldable, flexible to move and turn

• Large throughput and strong traction

• The equipment structure is relatively simple, making maintenance and repair more convenient

Wheel Compost Turner

• Simple structure, easy maintenance, and low failure rate

• High compost turning efficiency, and the organic fertilizer content is as high as 100%

• Due to the rotational motion of the roulette turner, uniform turning of organic waste is achieved

• Rotation speed, turning angle, and height adjustable parameters

• Equipped with an automated control system to ensure the stability and consistency of the pile-turning process

Industrial Composting System

Static Compost Covering System

The film rolling machine is a piece of equipment commonly used in industrial compost equipment to cover and protect the compost pile. By mechanically rolling and unrolling, wool mats or films are covered on the compost pile to provide functions such as heat preservation, moisture retention, and shading, and promote the decomposition and maturation process of the compost.

Fermenter Tank

The fermentation tank in industrial composting equipment is an important part of the fermentation and maturation of organic waste. The fermentation tank adopts a sealed fermentation method and provides an environment where temperature, humidity, and ventilation conditions can be controlled to promote the microbial decomposition process of organic waste.

• 10 hours of harmless treatment

• Intelligent temperature control system (80-100℃)

• Small footprint (10-30㎡)

Commercial composting system is an commercial fertilizer equipment system used to process organic waste and convert it into high-quality organic fertilizer.

Compared with traditional composting methods, the advantages of commercial compost machine :

• High degree of automation

The commercial composting system adopts automated control technology, which can realize automatic monitoring and adjustment of the entire composting process, reduce manual intervention, and improve the efficiency of organic fertilizer production.

• Large-scale production

Commercial composting systems can achieve large-scale continuous production and large processing capacity. They are suitable for large-scale places such as factories and farms to improve composting efficiency.

• Stable quality of compost

Commercial composting machine have more precise technical means to control temperature, humidity, ventilation, etc., which can ensure the growth and reproduction of microorganisms during the composting process, thus ensuring the stability of composted organic matter.

• Short composting time

The commercial composter adopts scientific composting technology and equipment, which can shorten the composting cycle, improve the production efficiency of organic compost, and reduce the production cycle.

• Environmental protection and energy saving

The commercial composting system adopts a closed composting process to reduce odor and pollutant emissions during processing, reduce the impact on the environment, and save energy resources.

• Product diversification

The commercial composting machine can adjust the composting process and raw material ratio according to different needs to produce a variety of specifications and types of organic compost products, such as powdered organic fertilizer, slow-release fertilizer, water-soluble fertilizer, liquid fertilizer, Granular fertilizer, etc. More market competitiveness.