How to produce organic fertilizer and compound fertilizer granules

2024-09-19The production of organic fertilizer and compound fertilizer granules usually requires the use of a fertilizer granulator and a composting machine.

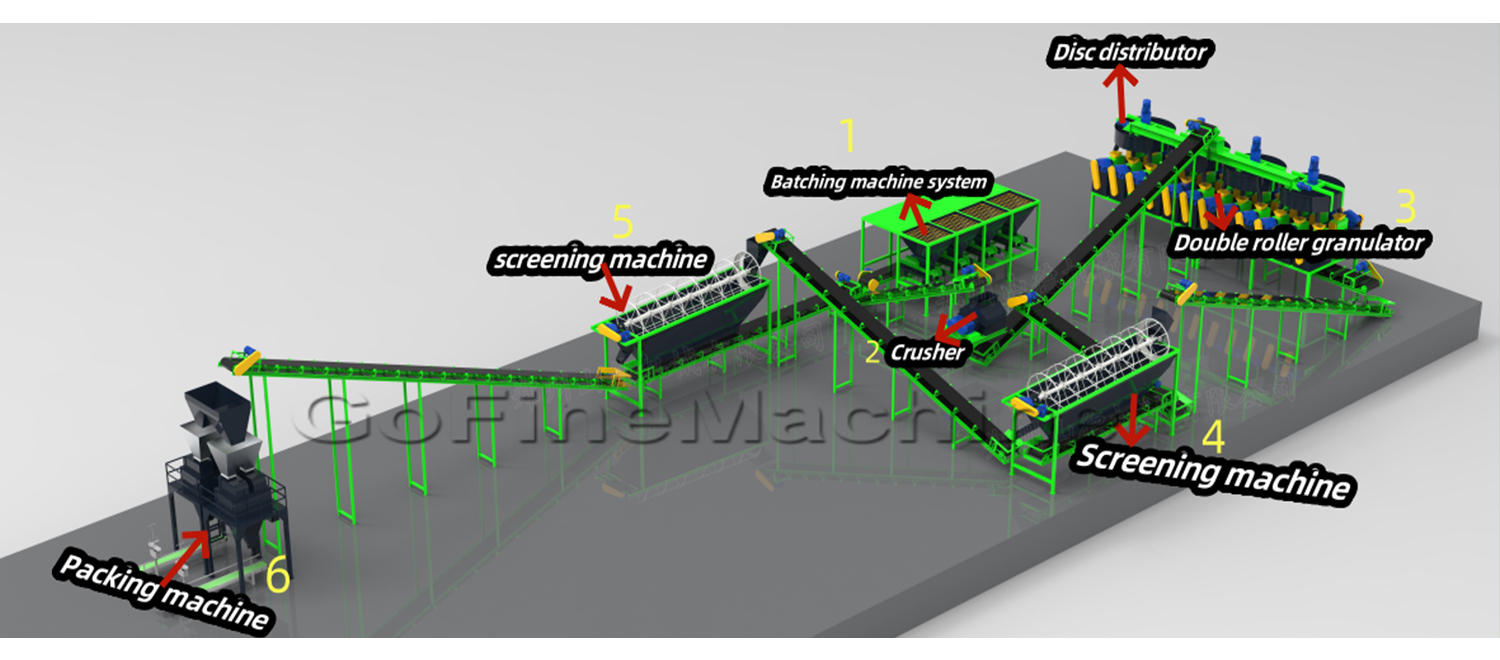

These include organic fertilizer compost turning machines, fertilizer granulators, batching machines, crushers, mixers, drying and cooling machines, screening machines, packaging machines, etc.

Next, I will give you a detailed introduction to the basic process of organic fertilizer and compound fertilizer granule production and related fertilizer equipment.

The process of producing organic fertilizer granules

1. Preparation of organic raw materials: Collect organic waste, such as kitchen waste, livestock, and poultry manure, straw, etc. as organic raw materials.

2. Composting: Send the organic raw materials into the composter, and compost them by stirring, ventilation, etc. to promote the decomposition and maturity of organic matter.

3. Production of organic fertilizer granules: Send the composted organic fertilizer into the fertilizer granulator, and make the organic fertilizer into granules through the pressing and granulation process of the granulator.

4. Drying and packaging: Dry the produced organic fertilizer granules and then package them for storage and transportation.

Compost turner machine:

Introduction to Fertilizer Equipment:

1. Composter: A composter is a device used for composting organic waste. It promotes the decomposition and maturity of organic matter through stirring, turning, ventilation, etc., and produces the preliminary raw materials of organic fertilizer.

2. Fertilizer granulator: A fertilizer granulator is a device for granulating organic fertilizer or fertilizer raw materials. It makes the raw materials into granules through extrusion, mixing, molding, and other processes, which improves the utilization rate of fertilizers and facilitates storage and application.

Fertilizer Granulator:

Process of producing compound fertilizer granules:

1. Raw material preparation: Collect various fertilizer raw materials, such as fertilizers of nitrogen, phosphorus, potassium, and other elements, as well as trace elements.

2. Mixing ingredients: Mix various fertilizer raw materials in a certain proportion to ensure that the granules contain a variety of nutrients.

3. Wet granulation or dry granulation: Send the mixed fertilizer raw materials into the wet granulator, add an appropriate amount of water, and make the raw materials into granules through the wet granulation process.

4. Drying and packaging: Dry the compound fertilizer granules produced by the wet method and then package them for storage and transportation.

Related equipment introduction:

1. Fertilizer granulator: Fertilizer granulator plays a key role in the production of compound fertilizer granules. Through different molds and processes, compound fertilizer granules of different specifications and ingredients can be prepared.

2. Composting machine: In compound fertilizer production, composting machine can be used to treat organic waste, provide the source of organic matter for compound fertilizer production, and ensure the full supplement of organic matter in the granules.

In summary, through the reasonable combination of composters and fertilizer granulators, high-quality organic fertilizer and compound fertilizer granules can be efficiently produced, providing high-quality fertilizer resources for agricultural production.