Best Organic Fertilizer Manure Dehydrator Cow Dung Dewatering Machine

2025-10-29As a leading fertilizer equipment manufacturer, we present this comprehensive guide to organic fertilizer manure dehydrator systems, with a special focus on cow dung dewatering machine technology. These machines serve as the crucial first step in transforming raw organic waste into valuable fertilizer, and understanding their operation is essential for any successful compost making machine setup.

The Critical Role of Dewatering in Organic Fertilizer Production

The organic fertilizer manure dehydrator represents the gateway to efficient waste management and fertilizer production. By removing excess moisture from raw materials, these machines:

-

Reduce transportation costs by up to 60%

-

Accelerate the composting process in your compost making machine

-

Improve the quality of final manure fertilizer products

-

Minimize environmental impact through better waste handling

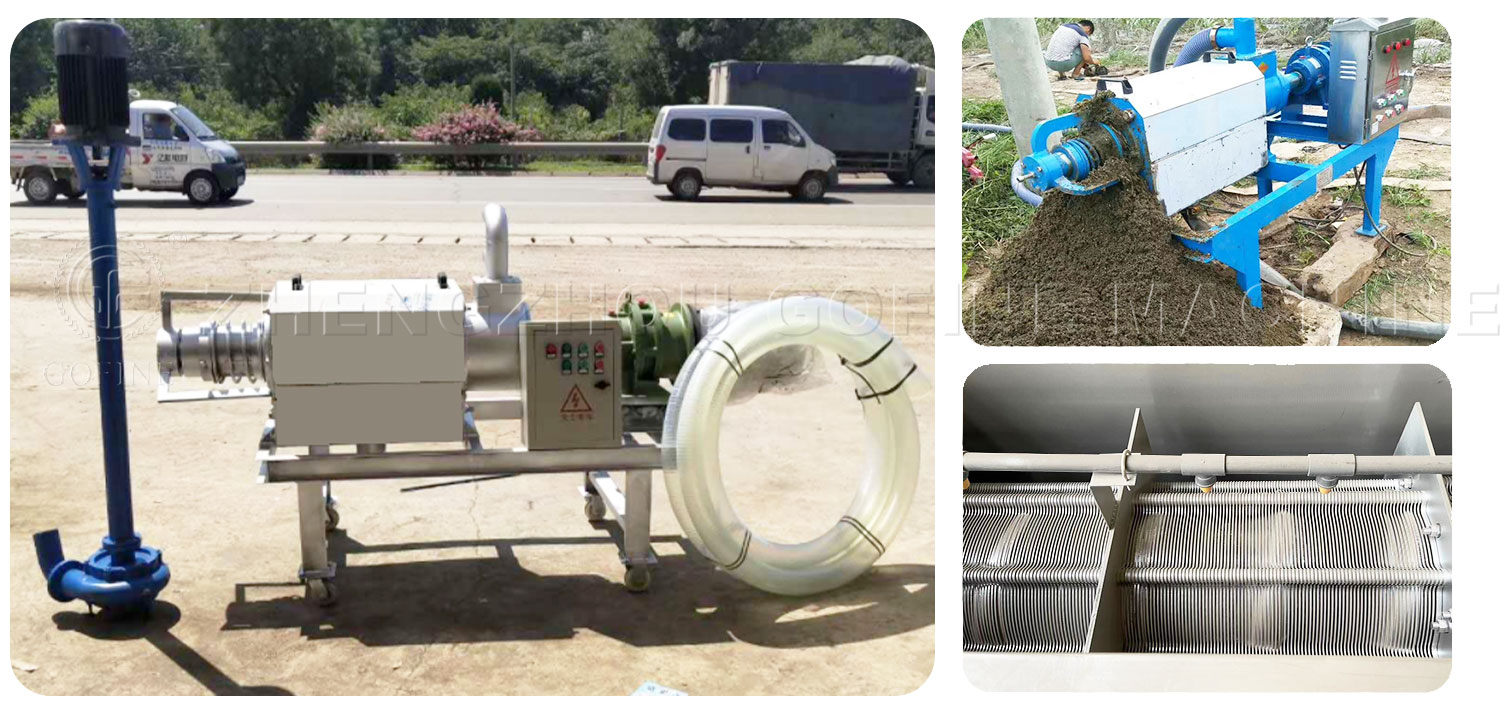

Screw Pressing Cow Manure Dewatering Machine: Technology Overview

The screw pressing cow manure dehydrator machine has emerged as the industry standard for efficient moisture separation. This technology utilizes a specially designed screw mechanism that applies progressive pressure to separate liquids from solids.

Key Technical Features:

-

Advanced Screw Design: Manufactured from high-chromium alloy steel for exceptional wear resistance

-

Automatic Pressure Adjustment: Self-regulating system maintains optimal dewatering efficiency

-

Stainless Steel Construction: Corrosion-resistant materials ensure long service life

-

Intelligent Control System: PLC-based automation for consistent operation

Applications Across Various Organic Materials

While commonly called a cow dung dewatering machine, this equipment handles diverse organic materials:

-

Dairy and Beef Operations: Processes cow manure with 75-85% moisture reduction

-

Poultry Farms: Effectively handles chicken manure with high uric acid content

-

Swine Operations: Processes pig manure with varying consistency

-

Agricultural Waste: Handles crop residues and green waste

-

Food Processing Byproducts: Manages organic waste from food production

Technical Specifications and Performance Metrics

Standard Cow Dung Dewatering Machine Capacities:

-

Small-scale Models: 2-5 m³/hour processing capacity

-

Medium-scale Units: 5-10 m³/hour for growing operations

-

Industrial Systems: 10-20 m³/hour for large facilities

Performance Characteristics:

Moisture Reduction: Typically achieves 65-75% moisture removal

-

Solid Recovery: Maintains 85-95% of nutrient content in solid fraction

-

Power Consumption: Energy-efficient designs consuming 5-15 kW depending on capacity

-

Operation Cost: Low maintenance requirements with easy-access components

Integration with Complete Compost Making Machine Systems

The organic fertilizer manure dehydrator serves as the perfect complement to your existing compost making machine setup:

Pre-composting Benefits:

-

Creates ideal carbon-to-nitrogen ratio for efficient composting

-

Reduces compost turning frequency requirements

-

Minimizes odor during the composting process

-

Produces consistent raw material for your compost making machine

Post-dewatering Advantages:

-

Solid output ready for immediate composting

-

Liquid fraction suitable for additional processing or direct application

-

Uniform material consistency improves compost making machine efficiency

More models of manure dehydration machines

Maintenance and Operational Considerations

Routine Maintenance Requirements:

-

Daily inspection of screw wear patterns

-

Regular sealing system checks

-

Periodic bearing lubrication

-

Screen cleaning and replacement

Operational Best Practices:

-

Pre-screening of raw materials to remove contaminants

-

Consistent feed rate maintenance

-

Regular monitoring of pressure parameters

-

Scheduled cleaning cycles

Choosing the Right Organic Fertilizer Manure Dehydrator

Selection Criteria:

-

Material Characteristics: Consider moisture content, fiber length, and abrasiveness

-

Capacity Requirements: Match machine size to your daily processing needs

-

Automation Level: Choose between manual, semi-automatic, or fully automatic systems

-

Future Expansion: Consider scalability for business growth

Supplier Evaluation:

-

Manufacturing experience and technical expertise

-

After-sales service and spare parts availability

-

Installation and training support

-

Performance guarantees and warranty terms

The organic fertilizer manure dehydrator, particularly the screw pressing cow manure dehydrator machine, represents a fundamental technology for modern organic waste management and manure fertilizer production. By efficiently separating liquids from solids, these machines create optimal conditions for your compost making machine to produce high-quality organic fertilizers.

Investing in the right dewatering technology can transform your operation from a waste management challenge into a profitable fertilizer production business. The improved efficiency, reduced costs, and enhanced product quality make the cow dung dewatering machine an indispensable component of any serious organic fertilizer production facility.

Contact us today to discuss your specific requirements and discover how our organic fertilizer manure dehydrator solutions can optimize your operation and increase your profitability in the growing organic fertilizer market.