Vibrating Screening Machine

- Information

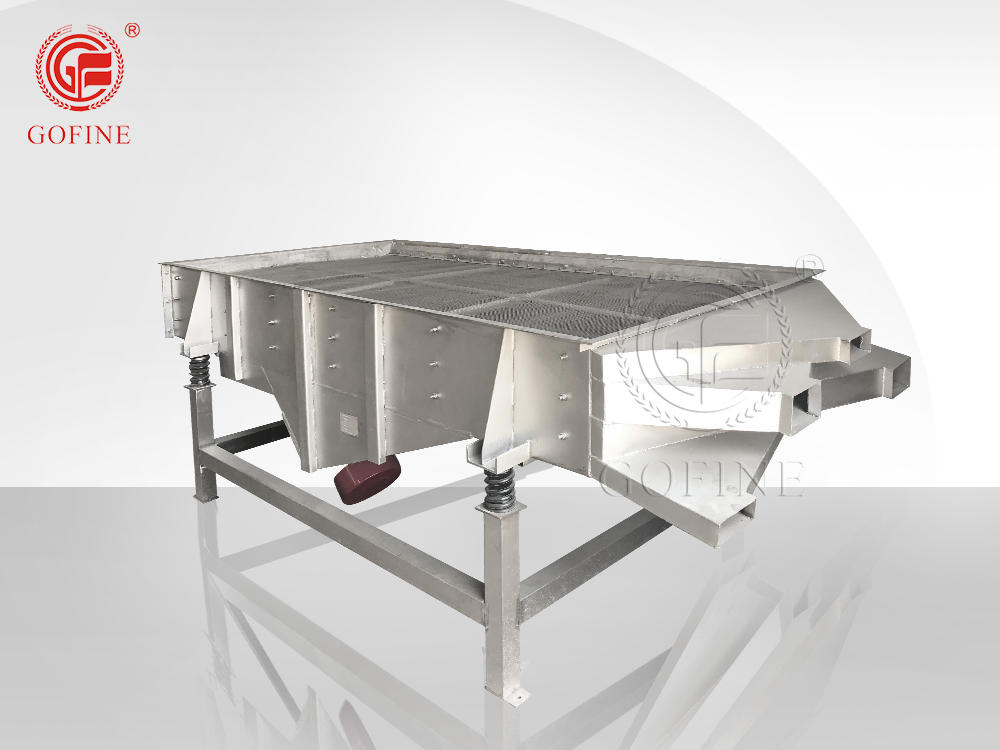

Introduction of Vibrating Screening Machine

Vibrating screening machine is a common material screening equipment. It can be used to screen powdery and granular materials such as fertilizer granules, feed, powdered organic fertilizer, sand, gravel, coal, etc. This equipment uses vibration to make the material move linearly on the screen, pass through the multi-layer screen, and screen and classify according to the particle size. Compared with the rotary drum screening machine, it occupies a smaller area and has higher screening efficiency.

Feature of Vibrating Screening Machine

1. Efficiency: Multi-layer screens can be configured according to the materials to meet the screening requirements of materials with different particle sizes, and the work efficiency is higher.

2. Uniformity: The vibrating working principle is adopted to make the materials more evenly distributed on the screen and avoid material accumulation and blockage problems.

3. Precision: The multi-layer screen design makes the material screening more precise and detailed.

4. Flexibility: Intelligent design makes operation more convenient, and the quasi-power and screen angle can be adjusted according to needs.

5. Self-cleaning: It is equipped with an automatic screen cleaning device, which can clean the screen regularly and have a longer service life.

6. Sealing: Equipped with a dust cover, it has good sealing and avoids pollution caused by dust.

Working Process of Vibrating Screening Machine

Materials enter the equipment through the feed port of the vibrating screen. The vibration force generated by the motor or exciter causes the screen surface of the screen machine to vibrate. The size and frequency of the vibration force can be adjusted according to the material characteristics and screening requirements. The materials are in a stratified state on the screen surface, with larger materials being blocked above the screen surface and smaller materials falling through the screen surface. Each layer of screen mesh has different apertures to achieve multi-layer screening. The screened materials are discharged from different discharge ports on each layer.

Technical Parameter of Vibrating Screening Machine

| Model | Dimensions (mm) | Material size (mm) | Screen surface inclination (°) | Amplitude (mm) | Number of layers |

| GF520 | 500X2000 | 0.074-10 | 0-7 | 4-8 | 1-5 |

| GF525 | 500X2500 | ||||

| GF530 | 500X3000 | ||||

GF535 | 500X3500 | ||||

| GF1020 | 1000X2000 | ||||

GF1025 | 1000X2500 | ||||

| GF1030 | 1000X3000 | ||||

| GF1040 | 1000X4000 | ||||

| GF1235 | 1200X3500 | ||||

| GF1540 | 1500X4000 |

Product Details of Vibrating Screening Machine