DAP compound fertilizer extrusion granulation production line solution

2025-02-22In modern agriculture and fertilizer production industries, DAP (diammonium phosphate) compound fertilizer is popular for its high nutrient content and good solubility. In order to improve production efficiency, reduce costs and reduce environmental pollution, more and more companies choose the extrusion granulation process to produce high-quality DAP compound fertilizer.

The DAP double-roller extrusion granulator production line adopts advanced dry granulation technology, which can directly extrude powdered raw materials into granules at room temperature, avoiding the high energy consumption problem of traditional wet granulation. Whether it is a fertilizer plant, agricultural enterprise, or fertilizer processor, this production line can greatly improve production efficiency while ensuring stable product quality.

Advantages of DAP compound fertilizer extrusion granulation production line

1. High efficiency and energy saving, reducing production costs

Dry extrusion granulation technology is adopted, no additional drying is required, and energy consumption is saved.

High material utilization rate, reducing raw material waste, and improving economic benefits.

2. Green and environmentally friendly, in line with the needs of sustainable development

No wastewater and exhaust gas emissions, in line with environmental protection standards, helping enterprises to achieve green production.

No binder in the production process, ensuring high purity of the final product and not affecting the fertilizer effect.

3. Uniform particles and stable product quality

Double-roller extrusion granulation technology is adopted to ensure consistent particle size and improve market competitiveness.

The particles have moderate hardness, are not easy to pulverize, and are easy to store and transport.

4. Easy operation and low maintenance cost

The equipment has a high degree of automation, simple operation, and reduced labor costs.

Key components are made of wear-resistant materials, with long service life and low maintenance costs.

Main equipment components of DAP compound fertilizer extrusion granulation production line

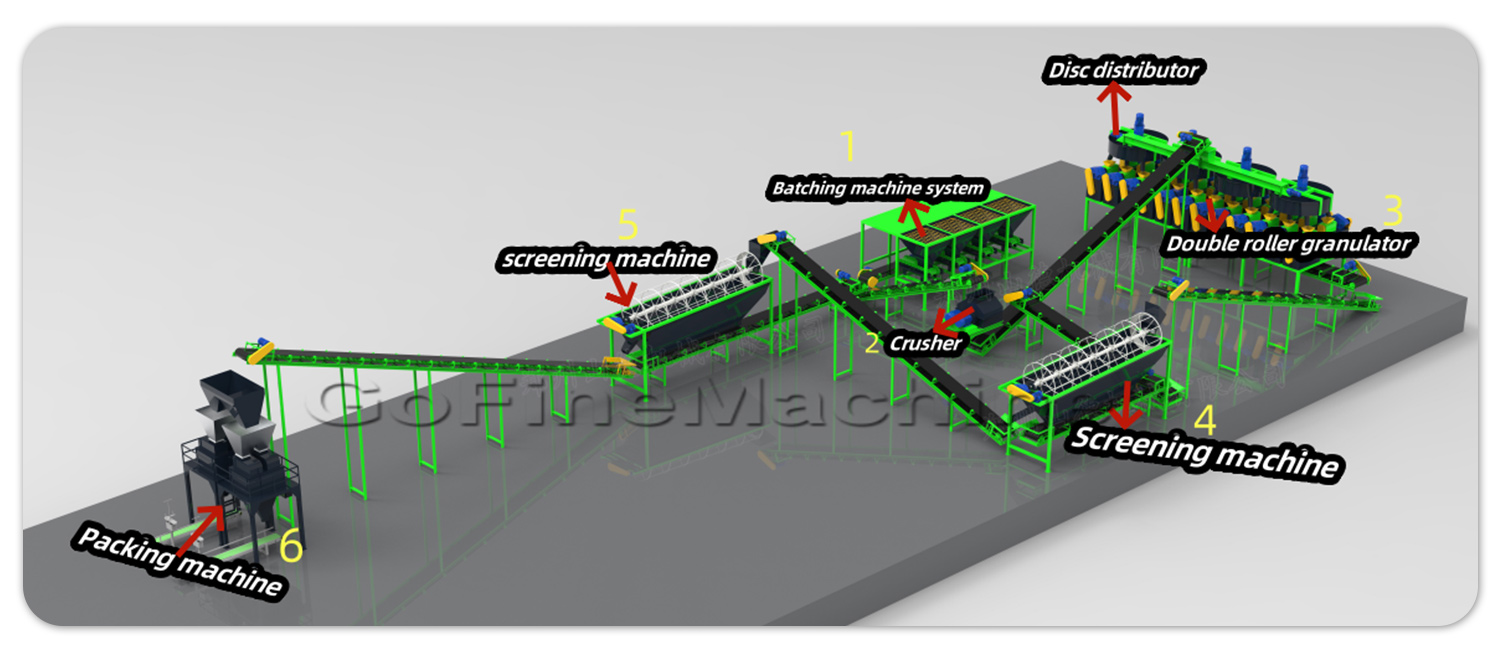

A complete DAP compound fertilizer extrusion granulation production line usually includes the following core equipment:

Precisely control the raw material ratio to ensure stable product quality.

Compatible with a variety of raw materials, such as diammonium phosphate, urea, potassium chloride, potassium sulfate, etc.

Adopt double-roller extrusion technology for efficient granulation without adding additional binder.

Adjustable roller gap to produce compound fertilizer granules with a diameter of 2-8mm.

The screening machine separates the finished granules from the powdered materials to ensure that the finished products meet market demand. The screened powder is conveyed to the granulator by a belt conveyor for re-granulation.

High-speed packaging to improve production efficiency.

Equipped with an automatic weighing system to ensure the accurate weight of each bag.

Provide an automated packaging production line to achieve integrated production of bagging, conveying, filling, sewing and palletizing.

· Use a belt conveyor or screw conveyor to realize production line automation. The specific equipment is selected according to the material.

Wide range of applications to meet various needs

The diammonium phosphate extrusion granulation production line is not only suitable for the production of diammonium phosphate (DAP) compound fertilizer, but also can be used for the granulation production of various fertilizers such as NPK compound fertilizer, ammonium chloride fertilizer, potassium sulfate fertilizer, biological organic fertilizer, trace element fertilizer, etc.

Whether it is a small fertilizer processing plant or a large fertilizer production enterprise, production lines of different sizes can be customized according to production needs to achieve personalized production.

Why choose our DAP compound fertilizer extrusion granulation production line?

Factory direct sales, and preferential prices: We provide cost-effective fertilizer production lines to ensure that customers get the best return on investment.

Support customization to meet different needs: Equipment can be customized according to production capacity requirements, raw material characteristics, etc. to ensure the best production effect.

Perfect after-sales and technical support: Provide one-stop services such as equipment installation, commissioning, personnel training, and after-sales maintenance to ensure worry-free production.

Global customer cases, quality assurance: We have successfully served fertilizer production companies in many countries and regions, and the quality of our equipment is trustworthy.

If you are looking for an efficient, environmentally friendly, and energy-saving DAP compound fertilizer extrusion granulation production line, please feel free to contact us! We will provide you with professional solutions and recommend the most suitable equipment configuration according to your specific needs.

Get a quote now and start a new era of intelligent fertilizer production!